COVID Can’t Stop Woodworking Students from Learning and Earning

Josiah Pole, a student at Boyceville High School in Boyceville, WI, gets some hands-on experience helping his dad build a shed.

A survey by the Woodwork Career Alliance reveals the unique challenges and ingenuity of teaching woodworking online and the determination of many students to earn their WCA credentials.

NELLYSFORD, Va. — The novel coronavirus pandemic forced the vast majority of schools across the United States and Canada to abruptly shut down for the remainder of the academic year and pivot to a crash course of online learning.

In spite of losing access to hands-on instruction, 179 students representing 13 high schools and postsecondary schools managed to earn their credentials, including Sawblade Certificates or Green or Blue Passport credentials, by successfully taking the Woodwork Career Alliance of North America’s (WCA) online credentialing test. All of these students were fortunate to have completed their machine operating evaluations before most states mandated schools to close to slow the spread of COVID-19.

Some of the instructors whose students attained their credentialswere among the WCA EDUcation members who participated in a survey conducted by the WCA. The survey sought to learn how high school and postsecondary woodworking instructors throughout the United States and Canada met the challenges of transitioning to teaching their students online including what types of information they taught in the absence of hands-on woodworking instruction.

The survey also asked teachers what resources they had developed or tapped into, including those available online to WCA EDUcation members. Their collective responses revealed the use of a wide assortment of educational tools including everything from assigning YouTube woodworking videos and home maintenance projects to quizzes on School.net and having woodworking students assemble UGears laser cut models. Among the WCA resources that were tapped include woodworking videos produced by Patrick Molzahn of Madison College, Fine Woodworking articles and videos and past state SkillsUSA project drawings.

The majority of teachers cited the challenge of transitioning online with very short notice, especially under the pressure of a global pandemic. Yet, many were able to relate silver linings gained from the experience.

“I think that one of the big positives that came out of all this is that although we were kicked out of the classroom, we still got kids certified with the Sawblade certificate and that’s sort of a neat thing,” said Scott Bruening, tech teacher at Kettle Moraine High School of Wales, WI. “We made lemonade out of lemons. That’s all we could do. Another good thing is that we got a crash course of doing things with online learning technology that could become the norm in the next five or 10 years.

Molly Turner, woodworking instructor at Ignacio School District of Ignacio High School, said it was challenging to engage students online, especially considering that woodworking is an elective course. “(N)o no one had time to prepare, plan or transition smoothly into homebound learning. It happened so quickly… On the plus side, it’s broken down some of the barriers of distance and forced everyone to become fluent in technologies that have been out there for a while, but maybe not used extensively prior to COVID-19: Zoom, Google Hangouts, Google Classroom, etc.”

“If there is any upside to this it will be that we are developing more teaching materials and expertise that will allow our students to work in a more independent and self-directed way: whether on a computer in our facility or at home,” said Doug Rappe, lead technical instructor of the Greater West Town Community Development Project of Chicago. “I am sure that some of the work we are doing in Google Classroom will be put to use for future classes for instance so that a student who needs extra review or misses a class can work on his or her own to catch up.”

Roger Peterson, woods instructor at Hurley High School District of Hurley, WI, said in an alternative to hands-on woodworking instruction, he assigned students “around the house” projects. “This is a challenging time and when students see everyone working together to get through this … THAT is what they are truly learning!”

“Hats off to all of the teachers and students who persevered during an extraordinarily challenging finish to the school year,” said Scott Nelson, president of the WCA. “Teaching woodworking online is less than ideal. That’s why I was s impressed by the creativity and resourcefulness that was demonstrated, including those who were able to complete the requirements for their Sawblade certificates and Passport credentials. I’m also extremely pleased that several of the instructors offered videos and documents they produced for the WCA to add to its online resource library to share with other woodworking instructors.”

Read the WCA’s COVID-19 survey report.

About the Woodwork Career Alliance

The Woodwork Career Alliance of North America was founded in 2007 as a 501(c)(3) non-profit corporation and is governed by a volunteer board of directors. The WCA’s mission is to develop and administer a unified set of Skill Standards for the wood products industry. Since 2011, WCA has developed observable and measurable performance standards and assessments for more than 300 woodworking machine operations. In addition, WCA has issued more than 2,500 credentials, a portable, personal permanent record documenting each holder’s record of woodworking skill achievements. More than 130 high schools and post-secondary schools throughout North America are WCA EDUcation™ members and a growing number of woodworking companies have joined the WCA as MANufacturing™ members. To learn more about the WCA and how to get involved with its programs, including sponsorship opportunities, visit WoodworkCareer.org.

The Trials and Tribulations of Teaching Woodworking Online

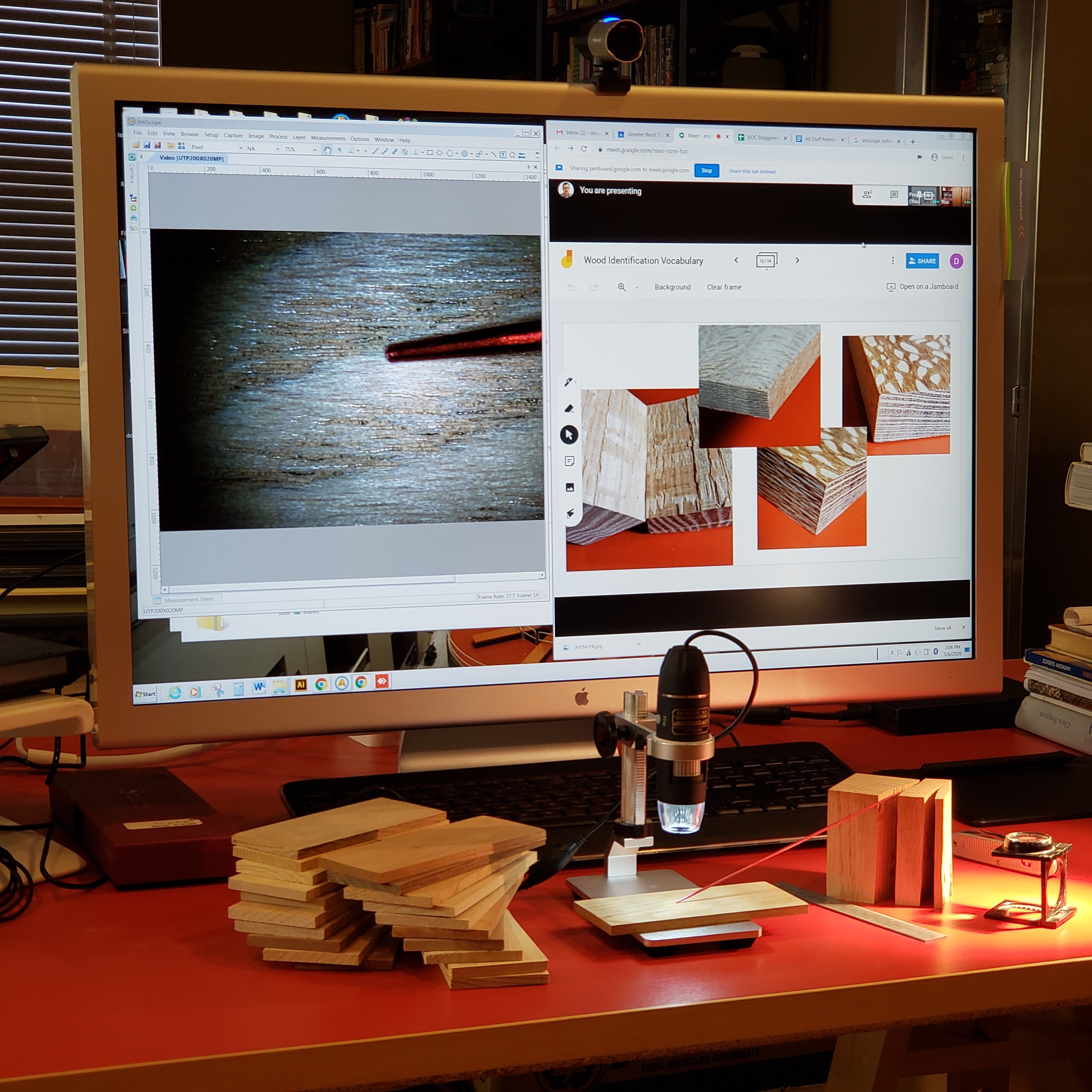

Doug Rappe of the Greater West Town Community Development Project used this setup for teaching a Google Classroom remote wood identification class.

The novel coronavirus pandemic has left an indelible mark on education institutions across North America by forcing the vast majority of schools to close for the remainder of the academic year.

The transition from teaching students in the classroom to online has most especially been fraught with challenges for woodworking instructors belonging to the Woodwork Career Alliance of North America. As if having to dispense with woodshop activities wasn’t hard enough, most teachers were given only a few days of notice that their school was being shut.

With so little warning, they scrambled to develop new lesson plans for online instruction on the fly.

Don Stoneburner, a student at Boyceville High School, proudly displays the WCA Sawblade certificate he earned after successfully completing the online test.

While online learning cannot make up for the hands-on experience of using equipment and tools to create wood projects, woodworking instructors participating in a survey of the Woodwork Career Alliance of North America explained how they revamped their curricula to incorporate a variety of alternative coursework and online resources. This includes taking advantage of videos, woodworking articles, past SkillsUSA project plans and other materials available online to WCA EDUcation members.

In spite of the disruptions created by COVID-19, several of the high school instructors said they already had or were in the process or preparing students to take the online test to earn their WCA Sawblade Certificate. Fortunately these students had already been evaluated on machine setup and operation on jointers, table saws and other basic woodworking equipment before their schools closed.

Some of the key questioned posed in the WCA COVID-19 survey included:

- How have their programs been impacted by the coronavirus outbreak?

What types of information are they teaching online? - How many educators are accessing the WCA’s resource library and what materials are they using?

- What tools would they like to see added to the resource library?

- Would they be willing to “donate” resources they have developed for their program to the WCA’s tool box for use by their peers?

Survey Highlights

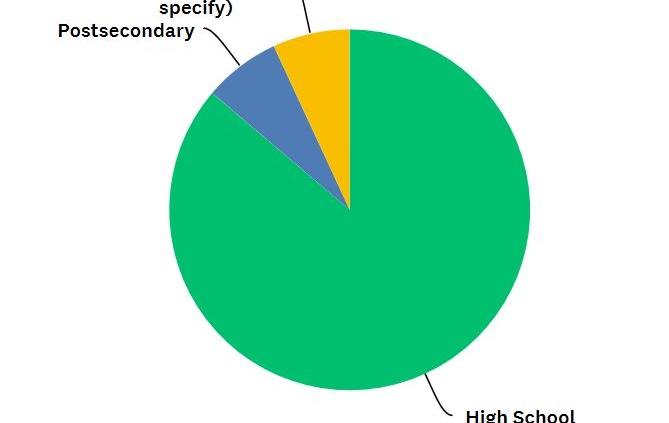

Twenty-eight woodworking educators responded to the survey, including 26 high school teachers, one college instructor and one community training program instructor.

Seventy-nine percent of the respondents said their schools were shuttered due to state stay-at-home orders and were teaching classes online. Fourteen percent said their schools were closed and they were not teaching online.

Forty-six percent said they were utilizing WCA online training resources, with several others indicating they planned to take a closer look at the videos and written materials available.

The bulk of the survey was composed of open-ended questions. Most of the teachers participating in the survey gave permission for information from their responses to be directly attributed to them In most cases they were sent questions to clarify or embellish some of their responses.

What follows are encapsulated summaries of how some of the woodworking instructors who took part in the survey have dealt with the shift to teaching classes online.

Frank Fetzer, woodworking, engineering and math teacher, Boyceville High School, Boyceville, WI

Fetzer said he featured measurement demonstrations and tests, YouTube woodworking videos and online discussions have been featured in online classes. In addition, he said he gave students “home maintenance assignments.” “These are not necessarily woodworking, but does give them something hands-on to do at home.” He also had students read/watch Fine Woodworking articles/videos with assigned write ups. Finally, he’s working on helping eligible students pass the WCA Sawblade test. Read expanded commentary.

Mickey Turner, woodworking 1, 2, 3 at John Holmes High School, Edenton, NC

“This whole thing has been hard for me to process,” Turner said. “I am a first-year teacher still learning the process and now this. Especially considering that I just got to the apply power tools agenda. There is no app for woodworking.” In the absence of being able to provide hands-on woodworking instruction for his students, Turner said, “I’ve been giving them bell ringers like school.net test questions, portable and stationary power tool safety procedures and quiz booklets. I have added some short instructional videos on portable power tools and some YouTube videos.”

Scott Bruening, tech education teacher, Kettle Moraine High School, Wales, WI

“I’m just finding it really difficult not being able to do anything hands-on at this point,” Bruening said. “I’m just trying to get more resources online for students to access. I’ve been using the older version of the textbook. We’ve focused on techniques and types of joinery in a visual manner, plus vocabulary, key terms and general knowledge items.” Read expanded commentary.

Marc Fry, woods manufacturing instructor, Green Bay East High School, Green Bay, WI

“I am struggling to find any visual examples, formats or layout of any woods instructor online,” Fry said. “Is there a way someone could provide Google classroom-ready slides and worksheets that are easily downloadable along with some kind of answer sheet and key?” Fry added that he taught four sections of Woods 1 and Advanced Woods 2. One online resource Fry mentioned using by name is edpuzzle.com.

Tom Hillstead, cabinetmaking instructor, Saint Paul College, Saint Paul, MN

Hillstead is the only college-level woodworking instructor to participate in the survey. He said he focused on teaching CAD/CNC software; laminates and surfaces; hardware used in casework and estimating. “I have 15 students this semester and they have adapted very well to our adjusted learning environment,” Hillstead said. “It’s not their first choice but… We have five courses this semester, three of which we were able to move online. One course, which was to run the last 8 weeks, will require “gap” instruction once we are able to return to the shop later this summer. It’s been an adjustment for everyone, but overall, it’s been positive. Even though the hands-on experience can never be replaced, my students and I have all learned a lot about the available technology, and I’m looking forward to incorporating where I can into future courses. Lots of videotaped demos!”

John Stearns, instructor, The MiLL and Peyton High School, Colorado Springs and Peyton, CO

In transitioning to online teaching, Stearns said he placed greater emphasis on reading and creating drawings, soft skills like leadership and personal growth, the business of woodworking and cabinet identification. He added that he has used old SkillsUSA project drawings in the WCA’s online resource for students to practice creating a bill of materials.

Roger Peterson, woods instructor, Hurley School, Hurley, WI

“I’m just trying to keep the kids engaged and understand how to do some things online,” Peterson said. “We are project planning for next year, revisiting some WCA Sawblade credentialing material (including measurement) and seeing how we can apply what we learned through the year to work on ‘around the house’ projects. This is a challenging time and when students see everyone working together to get through this … THAT is what they are truly learning!”

Tom Witt, woods manufacturing instructor, Monroe High School, Monroe, WI

“I am a dual credit teacher instructing 47 students online and have access to Patrick Molzahn’s information and videos on the WCA website,” Witt said. “We have focused on technical information and machine safety utilizing text and video demonstrations.” For his beginning level Woods Manufacturing 1 class, Witt said, “I am going through all the machines in the order that we use them to ‘square’ a single piece of stock including radial arm saws, jointers, planers and table saws.”

Doug Rappe, program coordinator, Greater West Town Training Partnership, Chicago, IL

“We are teaching the classroom portion of the curriculum remotely including math, reading, print reading and job readiness,” said Rappe, whose program trains economically disadvantaged adults for woodworking careers. Rappe said he has used some of the WCA videos produced by Patrick Molzahn, director of the cabinetmaking and millwork program at Madison College. Read expanded commentary.

Molly Turner, wood manufacturing instructor, Ignacio High School and Middle School, Ignacia, CO

“I’ve used Fine Woodworking/Fine Homebuilding online access to have students do research and read articles,” Turner said. “We are also getting ready to test students for their Sawblade certificates in my upper level classes. These students have reviewed machine set-up and operation standards. I’m also going to use the Sawblade certificate quiz as part of their final exam.”

Turner said she has utilized a Career Exploration packet that features “two career profiles including salaries, pros and cons, SkillsUSA framework and a resume,” plus UGears model kits with a project log and a product review at the end. “I’m brainstorming on project learning options that can be done at home with no tools, maybe pre-fabricated kits similar to UGears laser-cut models or paper automata karakuri projects,” she added. Read expanded commentary.

Christopher Randall, Asheville High School, Asheville, NC

“My candidates all did the Sawblade certificate performance widget right before we were all sent home,” Randall said. “I digitally reviewed so that they could take their online Sawblade tests. I’ve also used the free Fine Woodworking archives link on the WCA’s website.” Randall added, “Since turnout is low and I am at home practicing social distance and home schooling my own children, I am simply filming videos and sharing building projects with my students. They are sharing back with me what they can build at home.” Read expanded commentary.

Steve Swanson, Wauwatosa West High School, Wauwatosa, WI

“We are designing a kitchen using ADA standards and some household measurements,” Swanson said, adding that he utilized some of the measurement materials available in the WCA’s online resources.

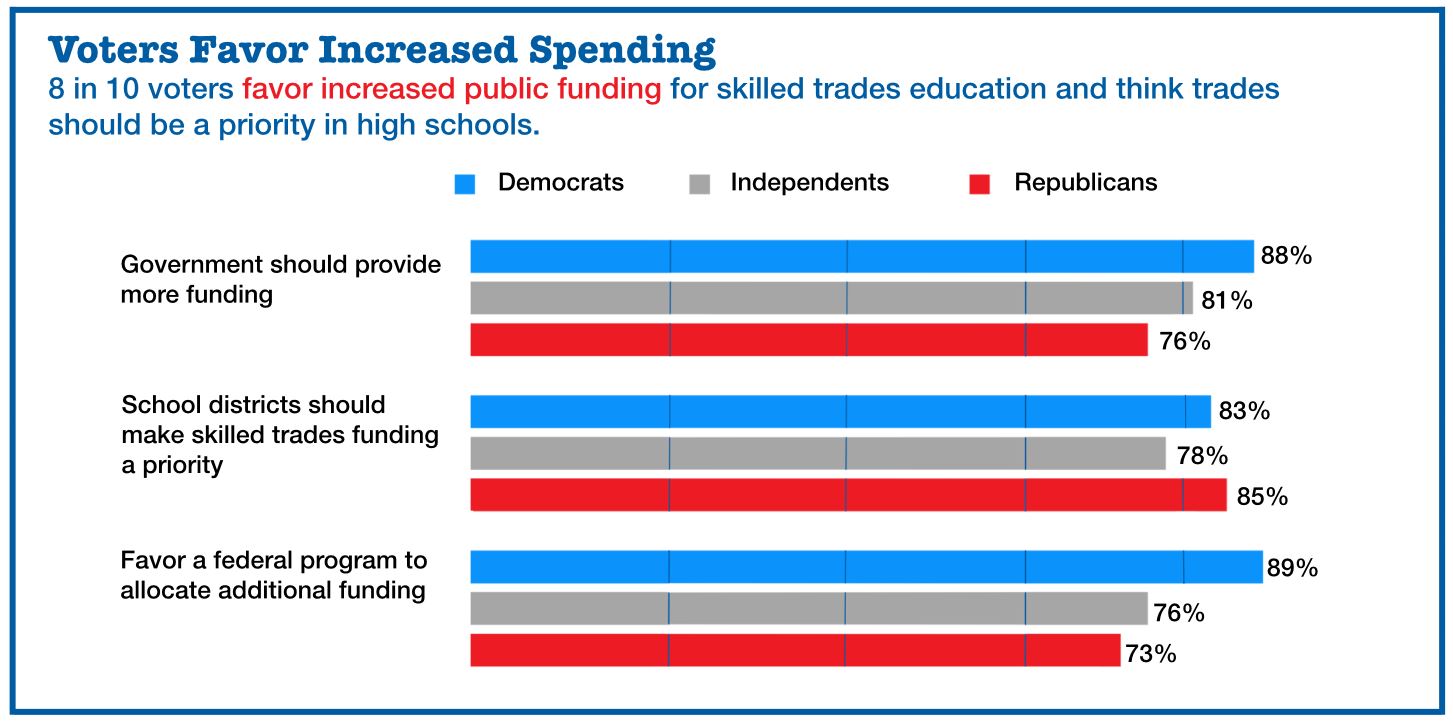

Studies Find Strong Support for Skilled Trades Education

Highlighted findings of the studies include:

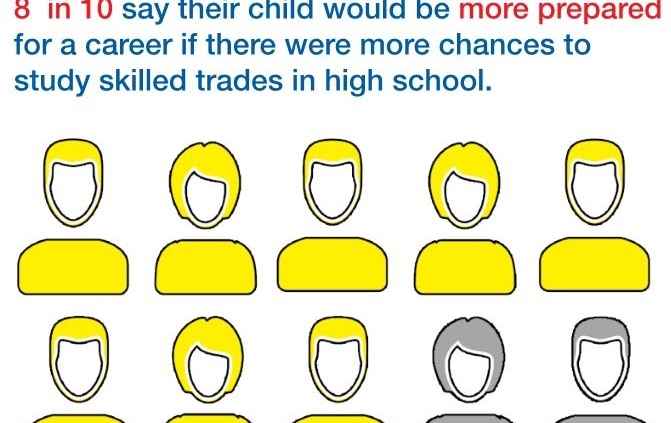

- More than 1 million students study skilled trades in high school.

- Eight in 10 voters favor increased public funding for skilled trades education and think it should be a priority in high school.

- Eight in 10 parents say their children would be better prepared for the future if they had a chance to study a trade in high school.

Each of the studies was conducted by an independent organization — JFF, a nonprofit that works to drive economic advancement for all Americans, and NORC, a nonpartisan polling organization at the University of Chicago.

According to HTFS, “Our hope was to start productive conversations about the potential of high school skilled trades education to uplift students, families, communities, and our economy.”

Building a Bridge Between Woodworking Education & Industry

Mark Smith, industrial technology teacher at Reed-Custer High School in Braidwood, IL, is in the news again. MultiBriefs, an online source of industry specific news, recently posted an article about Smith and his program.

Mark Smith, industrial technology teacher at Reed-Custer High School in Braidwood, IL, is in the news again. MultiBriefs, an online source of industry specific news, recently posted an article about Smith and his program.

“Supporting Student Success Through Industry Outreach” delves into Smith’s long-time and continuing efforts to forge relationships with the woodworking industry through a mix of press releases, social media posts and personalized thank you certificates and videos. The payback, the article notes, has been tremendous. “People from industry have generously given technical advice, career guidance, mentoring, equipment donations, financial support as well as internship and career opportunities.”

You can also learn about Smith’s views on the importance of promoting his program in an article WCA posted last July.

Students experience VR woodworking at The MiLL

The WoodEd Table, a virtual reality system for training students and novices how to operate basic woodworking machinery in a safe, dust-free environment, was implemented at the MiLL National Training Center in Colorado Springs, CO, earlier this year.

The Wood ED Table features four simulation modules: bandsaw, ripsaw, jointer and shaper. Users operate the system wearing a pair of 3D interactive glasses.

“In our classes there are always a few students whose fear of operating machines inhibits the growth of their skill,” said David Davis, instructor at the MiLL. “The WoodEd table can help (students) build skills without the fear.”

The MiLL (Manufacturing Industry Learning Lab) is an EDUcation member of the Woodwork Career Alliance of North America. Mimbus, developer of the WoodEd table, is a Gold sponsor of the WCA.

“Virtual reality is a tremendous tool for instructing students and new employees on the safe operation of equipment used in our industry,” said Scott Nelson, president of the WCA. “Young adults and kids are being raised on interactive video games that have a strong VR component. I think training simulators like the WoodEd table can help attract more youths into our industry.”

SCM organizes student tours of high-tech cabinet plants

SCM North America, along with two of its customers in Southern California – Excel Cabinets and Reeves Enterprises – recently provided students from San Jacinto High School’s Industrial Wood Technologies program the opportunity to witness a machine installation and cabinet manufacturing technology in motion.

SCM North America, along with two of its customers in Southern California – Excel Cabinets and Reeves Enterprises – recently provided students from San Jacinto High School’s Industrial Wood Technologies program the opportunity to witness a machine installation and cabinet manufacturing technology in motion.

Over the course of two days, this job shadow experience provided students of the San Jacinto, CA’s woodworking program, an inside look at factory performance optimization; SCM machine research and acquisition; and general day-to-day business operations. SCM North America is a Gold sponsor of the Woodwork Career Alliance of North America.

Day one: CNC nesting cell installation at Excel Cabinets of Corona, CA. During the installation of SCM’s X200 CNC nesting cell, students, Roman McNabb and Richard Zendejas, along with their instructor, Roy Castillo, were able to see the placement and leveling of the machine. This was followed by the final assembly, calibration, and quality assurance inspection orchestrated by one of SCM’s field service engineers.

Day two: Factory tour at Reeves Enterprises of La Verne, CA. During the visit at Reeves Enterprises, the students saw the process of building high-end commercial cabinets in a fully automated environment. Brad Reeves, vice president, explained how adjustments including cutting profiles, holes, and grooves are all supported in parametric cabinet design using G-Code programming. The code is created with Cabinet Vision, a computer automated drafting and manufacturing program to support a fully integrated screen-to-machine operation.

Experiential Education

“My students have a very manual and tactile experience in wood technology and it is in that background that many of the lessons we took part in with SCM were meaningful,” Castillo said. “The scale, efficiency, and workflow of these sorts of facilities gave my students access to what it might be like as a contemporary machine operator. The depth of parametric design and screen-to-machine operations supported our expectations in project planning. We found parallels in our plan of procedure project paperwork and the post processing/G-Code used at Reeves Enterprise;”

About San Jacinto High School’s Industrial Wood Technologies program

About San Jacinto High School’s Industrial Wood Technologies program

The Industrial Wood Technologies program provides students exposure to a wide array of tools and machinery: industrial hand, portable and stationary tools/equipment. Students enrolled in this program engage in an instructional environment where academic and technical preparation will focus on career awareness, career exploration and skill preparation in woodworking teachnologies. The knowledge and skills emphasized in this program include written and manufacturing activities.

Weinig Holz-Her Event Draws Record Crowd to Madison College

Weinig Holz-Her USA and Viking Machinery sponsored a day-long seminar on edgebanding at Madison College recently. Over 60 people attended, including owners and employees from more than a dozen shops located in Wisconsin and Illinois.

Madison College is an EDUcation member of the Woodwork Career Alliance of North America and Weinig Holz-Her is a WCA Gold sponsor.

Tim Keveney of Weinig Holz-Her started the day by talking about the development of edgebanding technology from 1950 to the present.

Tim Keveney of Weinig Holz-Her started the day by talking about the development of edgebanding technology from 1950 to the present.

Participants then separated into small groups for presentations on adhesives, edgebanding, and demonstrations using Madison College’s Holz-Her Streamer edgebander. Pat Stockinger of Jowat covered the various types of adhesives used for edgebanding. Randy Muelenberg of Rehau discussed various types of edgebanding materials that are available and how the material is manufactured. Kevin Gremillion of Weinig Holz-Her demonstrated machine setup and different edge applications, as well as demystifying the use of PUR adhesive.

Following a lunch catered by Viking Machinery, Gremillion presented an overview of edgebander maintenance. Participants had the opportunity to get their questions answered and spend time with the speakers throughout the day.

Madison College hosts two to three seminars annually that are open to the public. The next seminar will be held on Thursday, October 15. It will feature products and machinery manufactured by Lamello.

To receive notification of future events, subscribe to Wood Moves, an e-newsletter from Madison College’s Cabinetmaking & Millwork program, by emailing Patrick Molzahn at pmolzahn@madisoncollege.edu.

President’s Message: WCA Is Off & Running in 2020

2019 was a very productive year for WCA! We added 507 new individuals to our Passport credentialing program and awarded 418 certificates or credentials to individuals. This represents the largest number of credentials awarded in any one year in the history of WCA.

2019 was a very productive year for WCA! We added 507 new individuals to our Passport credentialing program and awarded 418 certificates or credentials to individuals. This represents the largest number of credentials awarded in any one year in the history of WCA.

We’re looking to build on the success of our credentialing program by certifying more Accredited Skill Evaluators (ASE) beginning this spring. We’re accepting online enrollment for ASE training scheduled for April 17 at Madison College in Madison, WI. We’re also working on the date for ASE training at Western Technical College in La Cross, WI. Contact me at snelsonwca@gmail.com if you want to receive details when they become available. Our busy spring schedule includes private ASE trainings in Massachusetts and Connecticut.

Also on tap in 2020, we will be concentrating on creating WCA 4.0. We are partnering with Woodworking Network on a survey of industry professionals throughout the U.S. and Canada. The results of this survey will help guide the development of WCA 4.0.

We’ll have more information to share about Industry 4.0 at the International Woodworking Fair in Atlanta this August. At IWF, WCA will offer a workshop on how to set up an in-house training program. Workshop attendees from all sizes and types of woodworking operations will receive a template that they can use to jumpstart developing a training program tailored to their specific needs. Plan on visiting us at IWF booth BC922.

Scott Nelson

President

Woodwork Career Alliance of North America

snelsonwca@gmail.com

Center for Furniture Craftsmanship Expands ‘Teaching the Teachers’ Scholarship Program

Center for Furniture Craftsmanship, a nonprofit woodworking school in Rockport, ME, has successfully raised $1 million to sustainably endow its Teaching the Teachers scholarship program. Launched as a pilot in 2018, Teaching the Teachers awards scholarships to schools and service organizations that teach woodworking to economically disadvantaged communities. Scholarships cover the full cost of enrolling a partner institution’s instructor in CFC’s workshops, so that he or she can return to their own programs with new woodworking skills and information.

As a result of its fundraising, CFC is able to offer one additional summer workshop scholarship for 2020 beyond the seven it has already awarded, and seeks nominations from new partner institutions. More information is available on the Center’s website or by directly contacting Director of Development Ellen Dyer. The nomination deadline is March 15, 2020.

The Teaching the Teachers scholarships that have already been awarded for 2020 have gone to Eldon High School in Eldon, MO; The MiLL in Colorado Springs, CO; Hudson River Maritime Museum in Kingston, NY; Narragaugus High School in Harrington, ME; Lansdowne High School in Lansdowne, MD; and Granite School District in Salt Lake City, UT. Additional partner institutions in the program are Alexandria City Public Schools in Alexandria, VA; Eastern Maine Community College in Bangor, ME; Greater West Town Community Development Project in Chicago; IL; Kids Making It in Wilmington, NC; Machias Memorial High School in Machias, ME; Messalonskee High School in Oakland, ME; and Salem-Keizer Public Schools in Salem, OR.

To advance Teaching the Teachers, the Center for Furniture Craftsmanship also affiliates with advocacy organizations that promote woodworking education for vocational training and economic development. Current affiliates are the Michigan Industrial and Technology Education Society, the Northern Forest Center, and the Wood Career Alliance of North America. Financial support for Teaching the Teachers is provided by the Mattina R. Proctor Foundation, the Horowitz Family Scholarship Fund, and the Betterment Fund.

The Center for Furniture Craftsmanship invites inquiries from potential institutional partners and affiliates. For more information, please contact: Ellen Dyer, development director, 207-594-5611.