The Southwest Colorado Education Collaborative has grown in size and scope, providing more resources and opportunities for students to hone their skills for potential entry into the trades.

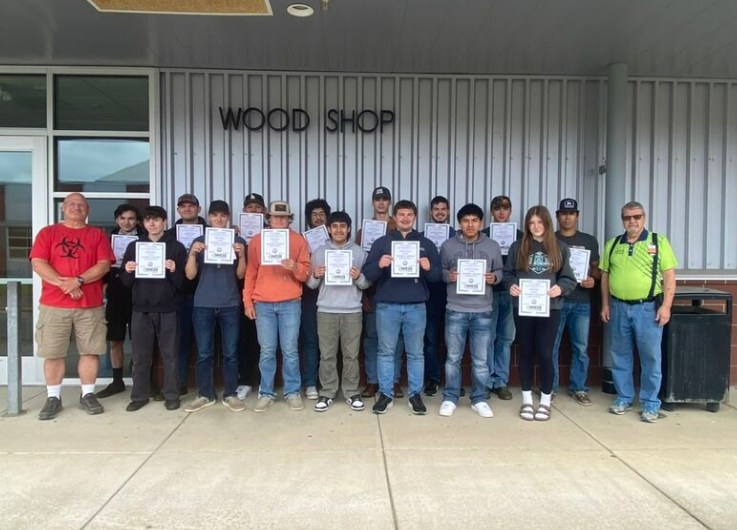

Students taking woodworking classes at Ignacio High School are among those reaping the benefits provided by the Southwest Colorado Education Collaborative.

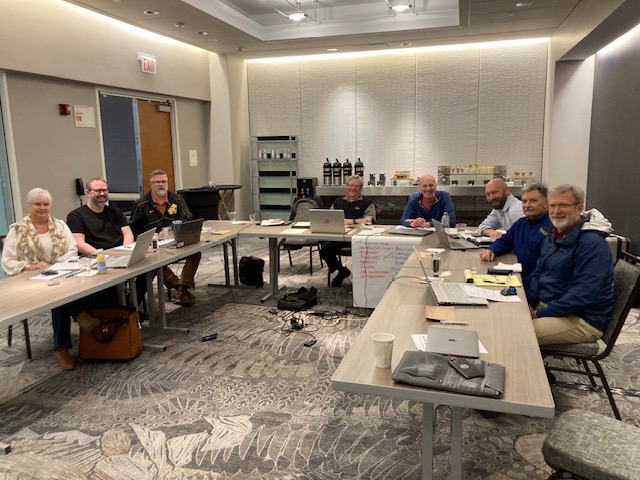

When Pathways checked in on the Southwest Colorado Education Collaborative (SWCEC) in Winter 2022, the innovative non-profit was still in the early stages of developing and sharing information and resources among its trade skills programs. That included shuttling shared-use industrial equipment from one program to another that none of the five small rural school districts could afford on its own. Two years later, the SWCEC has not only fine-tuned its approach to resource sharing, but it has also expanded to include four other area school districts, added career pathways, and embarked on a new program to partner with local businesses.

“The experiment is going pretty well,” says Molly Turner, a woodworking instructor at Ignacio School District. “It has been a learning experience to all. But every time we do an equipment rotation, training or anything else along those lines, our process gets better. We’re all trying to practice continuous improvement. The collaborative continues to grow and be able to provide more support and equipment to our community.”

“Our whole region is pretty rural,” Turner adds. “A huge goal of the collaborative is to bring equitable access for career readiness to all or our students. Because we are so remote, we don’t have the same resources that schools in Denver, Colorado and other front-range cities have. The collaborative has done a beautiful job of helping us bridge those physical gaps and make our small communities one large community so that we can share the resources we need to benefit our students.”

The Collaborative’s Origins and Growth

The SWCEC was formed in 2019, with a $3.6 million RISE grant, by teachers and school administrators of five neighboring school districts who wanted to offer students in rural areas the same opportunities that are provided in metro areas. The founding members of the SWCEC include the school districts of Archuleta, Bayfield, Durango, Ignacio and Silverton, plus Pueblo Community College and Fort Lewis College.

The organization’s website boldly proclaims, “The Southwest Colorado Education collaborative strengthens diverse communities by providing pathways in career readiness and higher education to build 21st-century skills and economically viable futures.” The SECEC’s initial focus was exposing students to career pathways like environmental science and the building trades, including woodworking.

“Since our initial grant, we have brought in another $5 million of funding,” says Jessica Morrison, executive director of the SWCEC. “We welcomed four additional school districts (Dolores, Dolores County, Mancos and Montezuma Cortez) to the table to try out our model. We also used part of the grant to expand into three additional career and college pathways including health sciences, education and hospitality/tourism.”

Turner notes, “Expanding the number of school districts involved in the collaborative from five to nine has allowed me to make connections with some other woods teachers from the region, which has been helpful. I have been able to meet with them at professional development days and learn from them and show them what I’ve been doing at my program. As an example, the new teacher at Dolores went to design school in New York and is very proficient at CNC and 3D modeling within CNC programming. He did a workshop with us that improved my CNC skills so that I can teach my students better. We also have been able to share projects and curriculums.”

Speaking of curriculums, Turner is a member of the National Woods Board, a new non-profit organization that is developing a scalable curriculum modeled after what was created for the Manufacturing Industry Learning Lab (MiLL) in Colorado Springs. That curriculum incorporates the Woodwork Career Alliance’s Skill Standards and Passport credentialing system to teach students woodworking skills that will make them workforce ready. Turner is an accredited skill evaluator of the WCA.

Speaking of curriculums, Turner is a member of the National Woods Board, a new non-profit organization that is developing a scalable curriculum modeled after what was created for the Manufacturing Industry Learning Lab (MiLL) in Colorado Springs. That curriculum incorporates the Woodwork Career Alliance’s Skill Standards and Passport credentialing system to teach students woodworking skills that will make them workforce ready. Turner is an accredited skill evaluator of the WCA.

Mobile Learning Lab Update

The SWCEC’s investment in industrial equipment and a trailer to move it from one school to the next came to fruition for the 2021-22 academic year. The shared equipment includes a Maverick Legacy CNC router, a MakerBot 3D printer, and an Epilog Fusion Pro laser. The lessons learned from the first-year experience have led to changes in how the program is administered.

“We used to rotate all three pieces at one time between the schools,” Morrison says. “We got feedback from the instructors not to ‘dump’ all of the equipment at one school at a time because it was way too much. So, we went back and refined the program so that a school district only has one piece of equipment at a time.

“The movement of the equipment is very important,” Morrison continues. “We’ve all been working together to figure out how to make this dynamic process work better to make sure the equipment moves smoothly to our shops. This equipment is not meant to be traveling around to different locations. Our operations manager has continually worked to finetune the system. Some of the equipment needs to be recalibrated every time it moves, so we now have that in our budget.”

“We have successfully done two rotations under the new program at this stage,” Turner says. “We figured out a sustainable rotation that works for the teachers with the help of the collaborative’s staff to handle logistics. I currently have the Maverick CNC router in my shop. It is getting ready to move to Durango High School next week. The 3D printer, which is on a slightly faster rotation, arrived in my shop two weeks ago. The equipment has been fantastic for our students. When those machines are in my shop, I try to have them being used as much as possible.”

“We have successfully done two rotations under the new program at this stage,” Turner says. “We figured out a sustainable rotation that works for the teachers with the help of the collaborative’s staff to handle logistics. I currently have the Maverick CNC router in my shop. It is getting ready to move to Durango High School next week. The 3D printer, which is on a slightly faster rotation, arrived in my shop two weeks ago. The equipment has been fantastic for our students. When those machines are in my shop, I try to have them being used as much as possible.”

In addition to the mobile learning lab equipment, the SWCEC has created MyTurn, a shared small tool “library.” Teachers can go online and order things like hand tools for running an HVAC system, electrical trainers and more, Morrison says.

Partnering with Industry

Among the SWCEC’s latest initiatives is developing a two-way connection to partner with area manufacturers and businesses.

“One of the big things we heard from industry is that access to work-based learning opportunities for students like internships, apprenticeships and summer jobs is really hit or miss depending on what school the student attends,” Morrison says. “Our biggest school district, Durango, has about 2,000 students K-12, and our smallest, Silverton, has only 84. The smaller districts cannot afford to staff someone to actively seek out student work opportunities with local businesses. We also realized that each district had different policies, paperwork requirements, etc.

“As a response to removing those barriers, we recently created Career Launch Southwest, a region-wide website that connects all industry in one spot to all students, parents and educators in the collaborative,” Morrison continues. “This will provide more equitable access for students to engage in workplace learning opportunities. For example, a student in Molly’s class at Ignacio could go onto this platform, create an account and search for summer job opportunities in their field of interest. The platform is also for educators. Molly, for example, can build a profile to find industry professionals to speak in her classroom.”

“I’m really excited about the database because we are one of the smaller school districts (about 700 students),” Turner says. “I would love to offer internships for my manufacturing students, but there is only one of me. Having the support of the collaborative means that I can help my students develop their resumes and spend some time in class to guide them to the website. We know that all of the industry partners on the site are looking for students. They will be able to able to find them easier. It’s really going to streamline the process and open up opportunities for my students.”

Strength in Numbers

Strength in Numbers

“When we come together collectively as one voice for the southwest region, we are able to bring more resources to our community, including millions in financial resources,” Morrison says. “As the first executive director of the collaborative my number one goal has always been equitable access to all students regardless of zip code.

Something that I’m really proud of is because of the facilitation the collaborative has done over the past three years, we’re seeing schools collaborate even outside of our space on things that have nothing to do with us. But I think we created the ground for that to happen. For instance, when a school district loses a teacher, they don’t call us first, they call their neighboring school district because we have helped foster cooperation among them. We’re now creating he interconnected we that is expanding what we do to the community.”

“This is good for our kids. It really is,” Turner says. “The collaborative has opened up communication lines and helped our student realize that they are part of a larger community than the southwest region because we are so spread out, we often think of ourselves as small little communities. It’s given our students the opportunity to be part of a larger community and everything from the inter-district job shadow field trips and the to the work-based learning opportunities that the collaborative organizes to sharing the equipment in our shops. Students are now getting to meet with-students of other school districts that they would not normally meet. There is a student advisory board that started this past fall to discuss what the collaborative is doing. It has made our community bigger and stronger than it was before.”

Learn more about the Southwest Colorado Education Collaborative.