Tim Fixmer, president and CEO of CCI Media, welcomes attendees to the 2019 Executive Briefing Conference held in San Jose.

The CEO of CCI Media discusses Woodworking Network’s commitment to presenting educational opportunities for the industry and his personal support of the Woodwork Career Alliance.

Tim Fixmer, president and CEO of CCI Media, has been a fixture of the woodworking industry for the majority of his long publishing career beginning with his early days at Woodworking & Furniture Digest, later retitled Wood Digest. His current role has him guiding the fortunes of FDMC and Closet & Organized Storage magazines, plus a host of trade shows and events that includes Wood Pro Expo, the Cabinets & Closets Conference & Expo, the Executive Briefing Conference and Canada’s Woodworking Machinery & Supply Conference & Expo. All of these properties are umbrellaed under the Woodworking Networking banner, which also serves as the online hub for posting industry trends and news, technical articles and videos that are regularly disseminated through the Daily Brief and other CCI Media-branded newsletters.

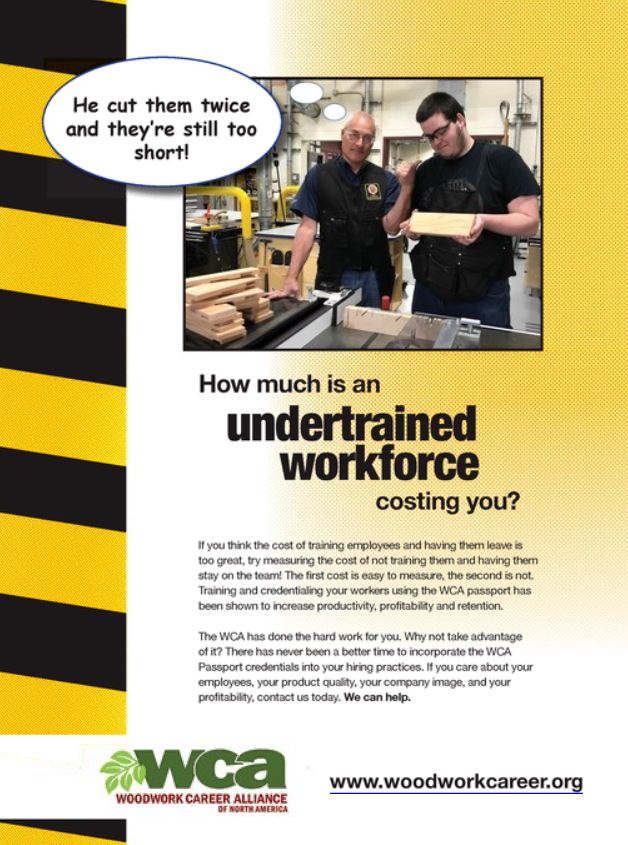

A common theme across CCI Media’s print, online and live event platforms is serving up content devoted to educating woodworking owners, managers and shop floor personnel on topics that can help them do their jobs better and make their companies more competitive. The Woodwork Career Alliance of North America has also benefitted significantly from Fixmer’s focus on education and training. FDMC has created and regularly run complimentary full-page ads promoting the WCA and earlier this year Woodworking Network signed on as a WCA Gold sponsor.

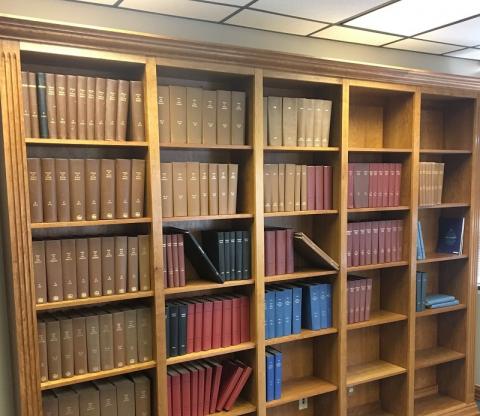

Fixmer partnered with the MiLL in Colorado Springs, CO, to create the Woodworking Netwrok Histroci Library. MiLL students built the bookcases to store bound volumes of Wood & Wood Products, FDM, Wood DIgest and related titles.

More recently, Fixmer and CCI Media teamed up with The MiLL (Manufacturing Industry Learning Lab) in Colorado Spring, CO, to develop the Woodworking Network Historic Library. Students at the MiLL, an EDUcation member of the WCA, built bookcases to store multiple decades of bound volumes of Wood & Wood Products, FDMC, Wood Digest and related publications. Woodworking Network has also partnered with Willy and Ingrid Volk of European Woodworking to create the Woodworking Network/Volk Scholarship to benefit deserving MiLL students.

WCA recently conducted a phone interview with Fixmer to learn more about what makes “Tim tick” when it comes to helping better the woodworking industry by offering learning opportunities and supporting the WCA credentialing program. Following are highlights of that conversation.

Woodwork Career Alliance: Most of your four-plus decades in trade publishing have been tied to the woodworking industry. What is it about the woodworking industry that continues to hold your interest after so many years?

Tim Fixmer: I’ve always been attracted to woodworking and enjoy working with wood as a hobby. My introduction to the industry came when I worked at a woodworking plant while I was in college. I took a semester off of school to assume the role of supervisor in a plant which was highly automated at that time. We built chopping blocks and cutting boards out of hardwoods. We had a rough mill operation all the way through to finished goods. I had first-hand experience of setting up and operating machinery such as a moulder, and focusing on plant efficiency, operations and workflow. I had a great mentor and as a very young person, I got some management experience at the same time. Once you’ve experienced the smell of hardwood in your nose, it’s hard to get rid of it. That experience led me to the industry and really made me love it.

After I graduated, I started working at Johnson Hill Press for an agricultural publication. As soon as we acquired Woodworking & Furniture Digest, I ran into my boss’ office and told him, “I got to work on this!” His response was, “No you don’t.” But I said, “I really do!”

I ultimately coerced him into giving me a shot. It was beginning of a real eye-opening experience for me. When I got out in the field and started talking to our woodworking readers it occurred me that the industry is filled with hard working, honest people of integrity who really care about the end product they are putting out. It’s all of these good people with a real dedication to their craft that makes my career extra rewarding.

WCA: What do you consider the biggest change the North American woodworking industry has experienced during your tenure?

Fixmer: CNC technologies, software, robotics and other forms of automation have rapidly changed the pace of the industry. I spent some time out of the industry, serving as publisher of magazines in high-tech markets. When I came back to the woodworking industry, I immediately recognized the huge impact technology had had on the marketplace during my eight-year hiatus. The industry itself transformed from one of mass production to a mass customization industry. The incredible advances in CNC technology allowed for that to happen.

The gain has not been without pain. The CNC era has created some huge challenges for woodworkers who have been resistant to embracing new technology. Many people are drawn to become woodworkers because they like to work with wood and think of themselves as craftsmen. It is our job as a media company to convert them from the craftsman mentality to adopting technology to become world-class manufacturers. They have to have that mentality regardless of size or how many employees they have. A one-man or one-woman operation has to see him or herself as a world-class manufacturer or it’s probably not going to work out well for them.

Fixmer’s support for WCA includes running compleimentary ads in FDMC magazine.

WCA: The industry’s struggles to recruit, train and retain skilled workers are well documented, including by your publications. As the industry’s workforce ages and workers retire there are not enough young people coming up through the ranks to replace them. Technology eliminates the need for a lot of material handling jobs but still the skills gap is growing. Do you have any ideas of how we can turn the tide on the skilled labor shortage?

Fixmer: I think those kinds of attitudinal things ebb and flow. The labor shortage has been caused in large part by our society’s attitudes of where we want our children to work. The atmosphere in which we grew up in as a nation. When our parents were coming out of World War II, there was a heavily positive recognition of manufacturing and manufacturing jobs. As our generation of Baby Boomers grew up, the parents who worked in the factories wanted “something better” for their kids and they wanted them to be educated. The blue-collar job was not the apple of their eye anymore. I think that as a result, they really wanted their kids to go to college and they didn’t see those two things as synonymous.

I recall a friend who went to college and then went info manufacturing. His parents said, “You spent all of that money to go to college to get a degree and now you are going to work in a factory. Are you nuts?”

Education is essential. I come from an education family. Both of my parents were teachers. When my dad couldn’t afford to raise a family on a teacher’s salary, he got a job as a text book salesman and then became a consultant for a textbook company related to the education field. My mother was the first kid in her family to go to college. She took a break to have kids and then went back and got her degree and taught for 22 years.

As a kid I always had a real affinity for education. I think that the education that we are going to be seeing over the next decade or so is going to be focused a lot on the trades because there are people who don’t want white collar jobs, they want to do things with their hands. There are people that we have to cater to as a society.

As we encourage our children to follow their hearts, there’s going to be more and more young people who are going to say, “I want to be in manufacturing.’ Our collective job as an industry is to make sure kids know about career opportunities in the woodworking industry — what they entail, what these jobs look like now and how they are changing. They need to know that woodworking jobs require computer knowledge to program a CNC machine to make a beautiful piece of furniture, a cabinet corbel or something else.

WCA: As head of Woodworking Network, you are involved in helping produce a lot of regional and national events both in the U.S. and Canada. All of them have a strong education component. How does offering these types of learning programs tie into the overall mission of Woodworking Network to serve the industry?

Fixmer: The whole premise of a media company like the Woodworking Network is to help our audience learn about new products and see new ways of doing things. We’re trying to help them become more productive and more cost-efficient in their operations. I think the role that education plays in our industry is very worthwhile because the state of which things are changing is increasing. Woodworkers need to stay on top of industry trends and they have to adjust because it’s either they move forward or move backward. They have to adapt to the new world order of manufacturing or else they are in entropy.

Our job is to deliver education and training in whatever medium our audience wants be it print, digital or events so that they can move forward. In any regard we have to understand the critical issues they are facing. What keeps them up on Sunday nights and what content can we provide to help them sleep better?

I think print and digital are great educational platforms, but nothing in my estimation replaces a face-to-face encounter between two people at a trade show. You can take all of the technology in the world and it is not going to be like sitting down over a cup of coffee with somebody and exchanging ideas. There’s something magical about that human interaction.

This also holds true for workshops. Really good, solid conference presentations are not sales pitches. They are conducted by knowledgeable professionals who will stretch the brains of the woodworkers who attend so that they go back to shops and implement concepts that make their businesses more efficient going forward. It’s an exploration of possibilities if it’s done right. I’ve lost count on how many sessions I have sat through where someone in the audience says, “I didn’t know things could be done this way.”

WCA: How does supporting the Woodwork Career Alliance dovetail with your mission to educate?

Fixmer: When Patrick Molzahn (director of the cabinetmaking program at Madison College) introduced me to the WCA and gave me a copy of the original skill standards booklet about 10 years ago, I said, “Man, you are sitting on a gold mine here.” I saw it as yeoman’s work that has to be done to create a pathway for Passport holders to increase their value proposition to their prospective, current or next employer.

I believe the WCA Is doing the right thing. They are the right entity in the right place at the right time with the right solution. For this reason, one of the criteria for the scholarship fund we started at the MiLL requires the student to have a WCA Passport.

I know it’s been a real challenge to get industry to embrace the WCA skill standards and credentialing program. Getting more woodworking companies to participate in WCA is like pouring water on a rock. It’s going to take a while for it sink in, but the industry is going to get it. The WCA Passport credentialing program is so important as a hiring tool, as a management tool, and as a training tool.

WCA: What most concerns you about the industry that gives you restless nights?

Fixmer: The woodworking industry has always had its ups and downs, without a doubt. There’s always been challenges. Our content team has focused on those challenges over the decades. But as difficult as things have gotten at times, one thing has not changed. Wood products and the woodworking industry are not going to go away. I think consumers’ affinity for wood and the creative ways in which it is utilized is going to continue on. That’s what drew me into the industry and I still feel that passion today.

Seventeen more educators recently completed their Woodwork Career Alliance (WCA) Skill Evaluator training at Madison College.

Seventeen more educators recently completed their Woodwork Career Alliance (WCA) Skill Evaluator training at Madison College.

WCA is ending the annual renewal process for all EDUcation members and I am happy to report that the renews are coming in at a very good rate. In addition, we have added 21 schools as

WCA is ending the annual renewal process for all EDUcation members and I am happy to report that the renews are coming in at a very good rate. In addition, we have added 21 schools as