National Woods Board Revs Up to Educate NextGen Woodworkers

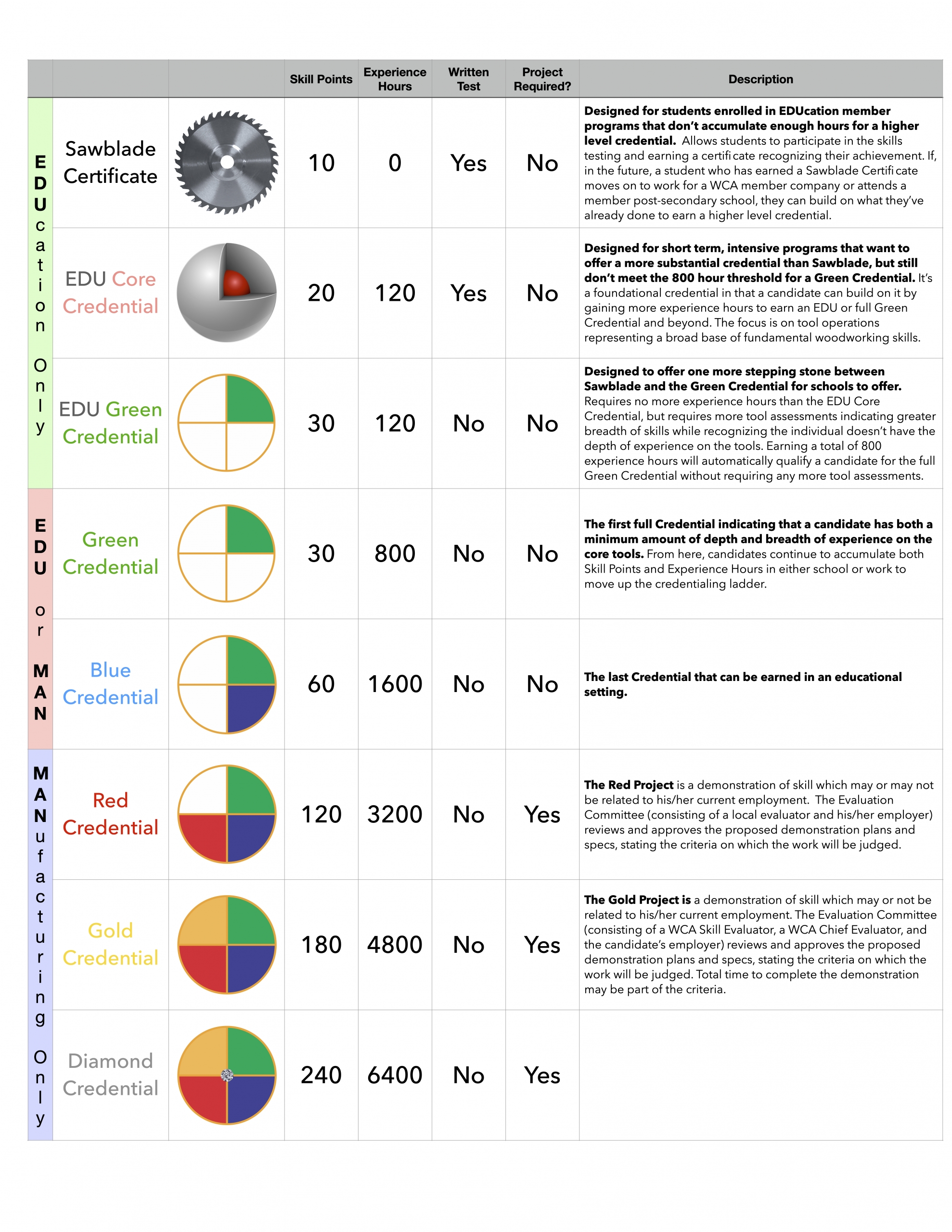

This new non-profit organization is developing a scalable curriculum that incorporates the WCA Skill Standards and Passport credentialing system to teach students woodworking skills that will make them workforce ready.

The MiLL in Colorado Springs, Colo., is the inspiration for the National Woods Board’s mission to bring high-caliber curriculum to high school woodworking programs throughout the country.

The woodworking industry’s struggle to recruit skilled workers is a well-documented, decades-old problem.

Case in point, according to a 2021 study by Woodworking Network and the Woodwork Career Alliance of North America, 73.8% of survey participants said it was “very challenging” to hire qualified workers for their manufacturing operations. Making matters even more disconcerting, 57.9% said hiring qualified candidates was “much more challenging” than it had been three years before.

Thomas Allott, manager of Stiles University and chairman of the new National Woods Board (NWB), said not only will the industry’s most deep-seated and biggest universal problem not fix itself the situation promises to only get worse as more and more Baby Boomer woodworkers retire over the next few years.

Allott pointed to what he dubbed “scary employment stats.”

“Our industry has a large concentration of workers between 45 and 65 years of age.” Allott said. “In the next 10 years, a majority of our workforce is likely to retire. It takes four years to educate a student so we can’t wait. We need to start doing something about it now.

“The other crazy thing is there are 8.8 million jobs that are unfilled,” Allott continued. “Ten percent of them are in the wood manufacturing and construction industries. Our industry is dying, if you will, because we don’t have people to fill it.”

Added to those troubling numbers, Allott said the woodworking profession continues to face the “general public’s perception that our industry is old, that there is not a lot of technology, it is not fast paced enough, and it is not evolving. We know that none of that is true. Our industry is automating more and more. Robotics are starting to come into play. Software is driving all of our design and manufacturing processes. We have to do a better job of telling our story and getting people ready to work in this industry because no one else is going to develop the talent for us.”

Enter the National Woods Board

![]() According to its website, “The National Woods Board was created to help face the challenge of labor shortages head-on by making trade education accessible within high schools around the United States, creating career opportunities, and addressing the industry’s workforce needs.”

According to its website, “The National Woods Board was created to help face the challenge of labor shortages head-on by making trade education accessible within high schools around the United States, creating career opportunities, and addressing the industry’s workforce needs.”

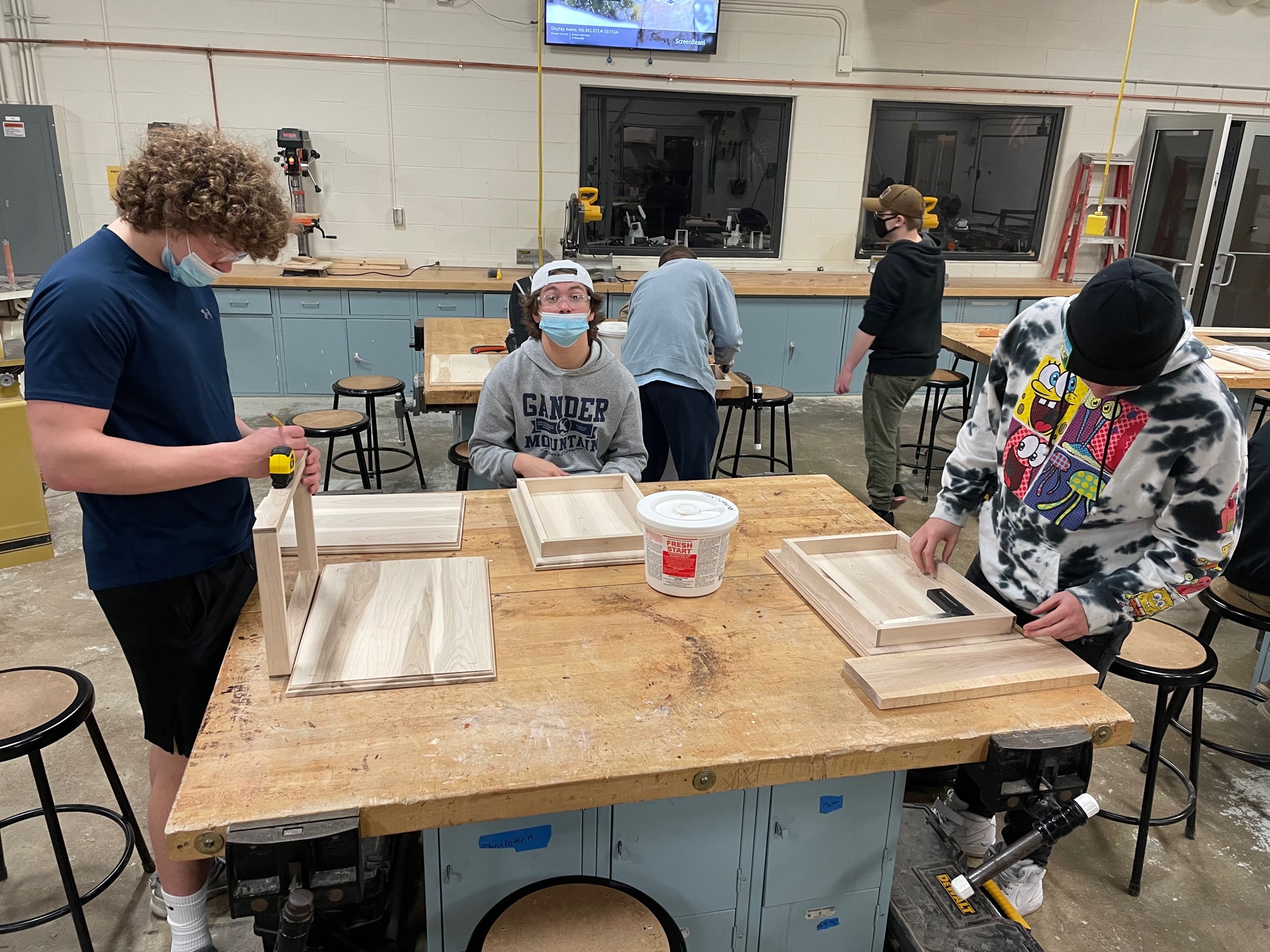

To achieve its mission, the NWB, which launched last year, seeks to develop curriculum that is scalable for high school woodworking programs regardless of the location or population of their district to teach students the essential skills they need to launch successful woodworking careers. In addition, the NWB seeks to forge strong symbiotic partnerships between the wood products industry and local high school woodshops.

The working model for NWB’s grand plans is The MiLL (Manufacturing Industry Learning Lab) in Colorado Springs, Colo. The MiLL is a well-equipped, 46,500-square-foot training center that opened in 2017. Since its inception, The MiLL has garnered an avalanche of wide-ranging support from woodworking machinery and supply companies. Allott said The MiLL trained 422 students in cabinetmaking, construction, and welding during the 2022-23 school year.

The NWB, Allott said, is not focused on replicating The MiLL’s physical footprint in other parts of the country. Instead, the NWB seeks to help high school woodworking programs maximize their ability to prepare students to be workforce ready based on learning industry standards inspired by the The MiLL’s project-based curriculum.

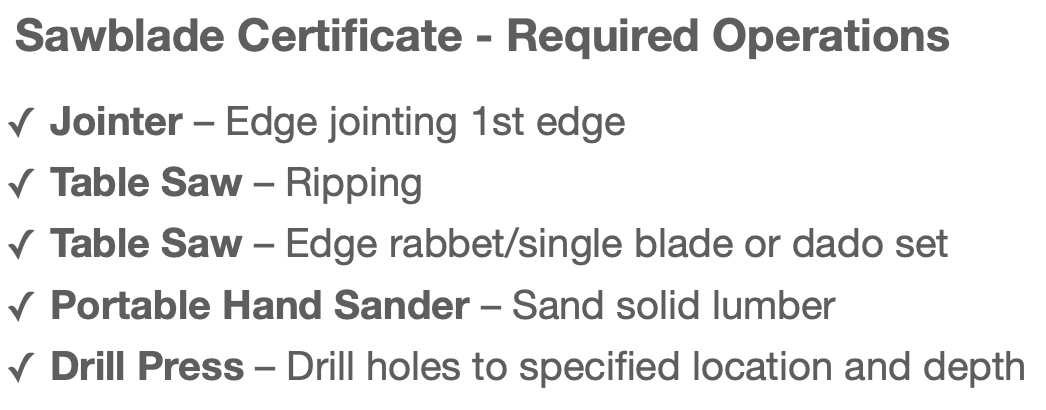

The curriculum would incorporate the Woodwork Career Alliance of North America’s Skill Standards and Passport credentialing program.

“The WCA is the industry standard for skills evaluation and accreditation,” said Allott, who is a member of the WCA Board of Directors. “It’s the only thing that we have in this industry that’s been consistent for more than 15 years now. That’s our industry standard but we have no way to get students through that industry standard if they continue to build birdhouses. We need to start teaching our students about industry and then be able to credential them. That allows them to go into industry a lot easier and gives the employer the justification that the person they are hiring is a skilled, certified worker.”

“Our industry is made up of two different segments,” Allott said. “We have wood products manufacturers, and we have suppliers. Both segments are struggling to find good, skilled people. The school districts have plenty of students who do not plan to go directly to college, if at all, after they graduate. They will be looking for good paying jobs. What’s missing right now is a scalable curriculum that helps prepare those students for rewarding woodworking careers.

“The National Woods Board would provide the curriculum to local school districts,” Allott continued. “The school districts would partner with their local suppliers and/or woodshops, who would support high school woodworking programs with donations of funds, equipment or supplies. The goal would be to create local ecosystems across the country where students can get hired to a good paying job offered by companies looking for well-trained employees. This is the key that is missing right now and the NWB is the thing that is going to make it happen.”

NWB Lays Foundation to Take Next Steps

Over this past year, Allott and the NWB board have stepped up their efforts to get the word out and rally industry support and raise funds to help the NWB achieve its goals. Allott recently followed up a presentation about the NWB at the AWFS Fair in July with one at the Executive Briefing Conference (EBC) in September.

“We have a great team in place to make the National Woods Board successful,” Allott said. “The NWB board is special because it is made up of 13 different individuals with different backgrounds. We’re not all woodworkers. We have educators and educational administrators, media pros, business executives, and industry suppliers. We’re a very well-rounded group that takes the various aspects of the industry into account when making decisions.”

The members of the NWB board are Chairman Thomas Allott (supplier), Brian Donahue (supplier), Dean Mattson (educator), Jason Howell (supplier), John LeTourneau (executive coach), Kelly Victor-Burke (manufacturer), Molly Turner (educator), Rob Roszell (media), Scott Robinson (manufacturer), Shane Skalla (educator), Tim Fixmer (media), Tim Kistler (educator), and Amanda Conger (executive director).

2023 has been a busy year for the NWB board. Key accomplishments include:

- Obtaining status as a 501(c)3 nonprofit organization. This allows donors to write off their financial contributions on their taxes.

- Updating and expanding information on the NWB’s website: nationalwoodsboard.org. Interested parties can learn more about the NWB, its mission, and its activities.

- Hiring Amanda Conger to the newly created position of executive director to handle day-to-day responsibilities and help guide the NWB to achieve its goals. Conger has a wide range of industry experience and has made a great number of contacts through her leadership positions with Cabinet Makers Association and the Association of Closet and Storage Professionals.

- Presenting at major industry events including the AWFS Fair and Executive Briefing Conference. Allott is scheduled to present a keynote address at the 2024 Closets Expo/Wood Pro Expo Illinois next April.

“Now that we have a solid foundation in place, we are developing funding sources to raise at least $100,000 in seed money by September 2024. The funds will be used to modify and update the curriculum for the first of four cabinet programs and to set up a platform to distribute them to high school woodworking programs,” Allott said. “We’ve made some headway. We’ve had a lot of donations come in and we’re looking into grant opportunities, but we still have our work cut out to get to where we need to be.

“The bottom line is we need industry’s support,” Allott said. “You can’t expect the next generation of skilled workers to come out of nowhere. If we don’t have the support of industry, this will never take off. All stakeholders need to put their money where their mouth is. Everyone agrees that the skills gap is industry’s greatest challenge, but no one is doing anything about it. They’re all waiting for someone else to do it.

“The NWB is here to fill that void,” Allott concluded. “There is no better time to do it than now. We have the curriculum, and The MiLL is proof of the concept. Now all we need is industry’s support.”

Learn more about the National Woods Board and make a donation at nationalwoodsboard.org.