Kettle Moraine High School Embraces WCA Core Credential

Editor’s note: A year ago, Pathways featured a profile of the robust woodworking program at Kettle Moraine High School. By happy coincidence, dozens of participating students were also members of the high school’s varsity football team which had just won the state of Wisconsin’s 2022 football championship. While the Kettle Moraine Lasers came up short in their playoff bid for a title repeat last Fall, the woodworking program continues to build on its impressive record of growth and achievements.

Editor’s note: A year ago, Pathways featured a profile of the robust woodworking program at Kettle Moraine High School. By happy coincidence, dozens of participating students were also members of the high school’s varsity football team which had just won the state of Wisconsin’s 2022 football championship. While the Kettle Moraine Lasers came up short in their playoff bid for a title repeat last Fall, the woodworking program continues to build on its impressive record of growth and achievements.

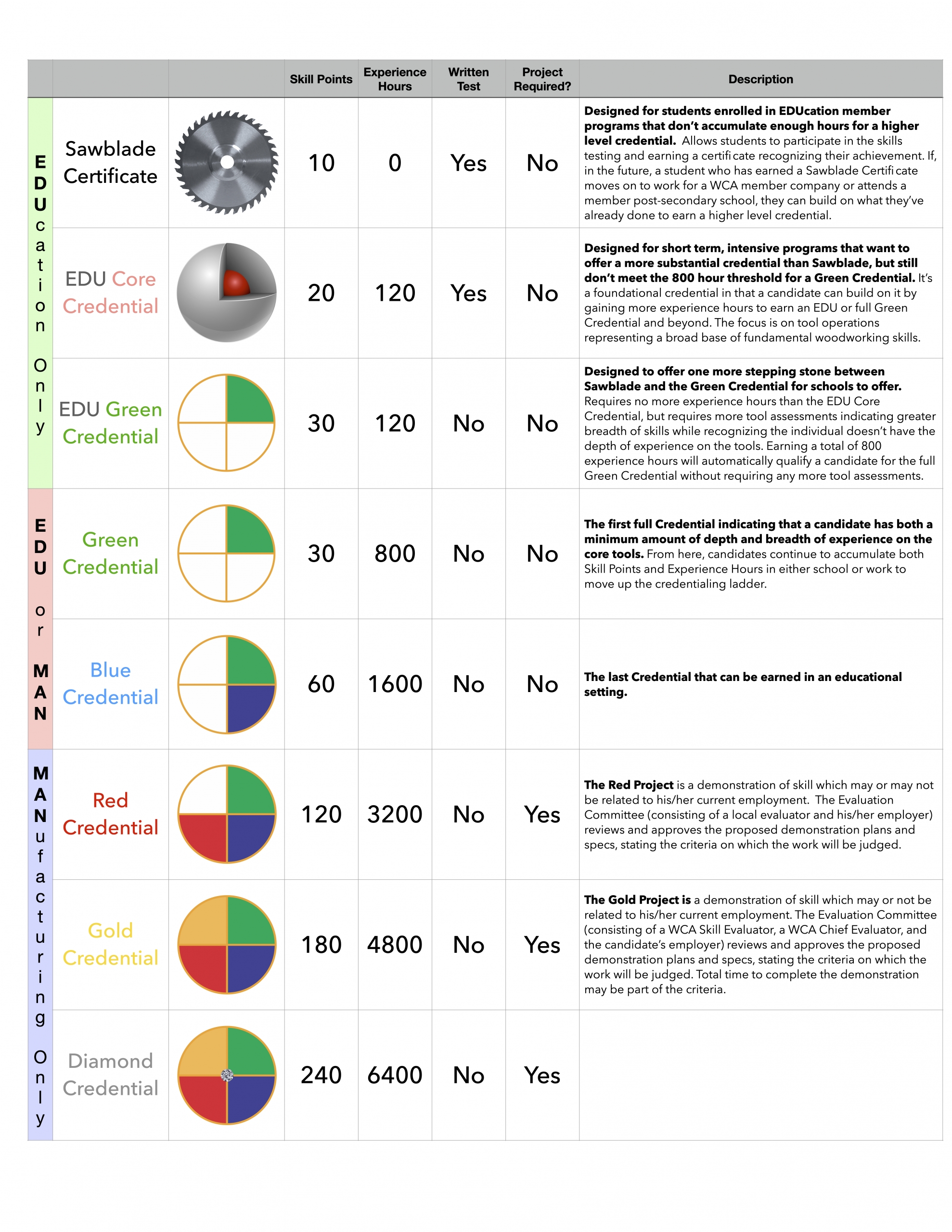

Perhaps most notably, the program led by technical education teacher Scott Bruening, is making the pivot to meet more rigorous requirements laid out by the Wisconsin Department of Workforce Development to continue receiving CTE incentive grants. As a result, Kettle Moraine woodworking students will not only be challenged to earn their WCA Sawblade Certificates this spring, they will also be evaluated and tested to receive the Core Credential, the next level of the WCA’s credentialing scheme. Earning core will further demonstrate a students’ readiness to join the woodworking industry if they so choose.

In 2016, the Wisconsin Department of Workforce Development (WDWD) approved the Woodwork Career Alliance’s Sawblade Certificate as a recognized credential of its Career Technical Education Incentive Grant program. The incentive program was created “to support and strengthen quality CTE programming that results in industry-recognized certifications that help to mitigate workforce shortages.” As a result of the WDWD’s approval, high school woodworking programs using the WCA’s Skill Standards and Passport credentialing program became eligible to receive grant awards of up to $1,000 per graduating student who earned their Sawblade.

Entering this academic year, the WDWD raised the stakes for CTE Incentive Grant eligibility. Students are now required to earn the WCA’s Core credential for their high school woodworking program to receive a grant award. The Core credential, introduced in 2021, builds on the Sawblade Certificate that has long served as the cornerstone for recognizing a student’s ability to safely set up and operate basic woodworking machinery in accordance with the WCA’s Skill Standards. To achieve the Core credential, a student must earn the 10 skill points required for the Sawblade Certificate plus an additional 10 skill points while also accumulating at least 120 hours of hands-on woodworking experience. Students must also pass separate online tests for Sawblade and Core awards.

In a letter to Wisconsin EDUcation member instructors, Scott Nelson, president of the WCA, noted that the WDWD made the change based on feedback from wood products manufacturers in the state who opined that the skills required by the Core credential better prepared interested students to enter the workforce. “As a past architectural woodwork manufacturer, I had to agree that the Core Credential does make the student a much more employable person directly out of high school,” Nelson wrote. “Our board of directors agreed and gave the state the OK.” The bottom line, Nelson added, “(T)he WCA’s mission is to help provide a trained workforce for the secondary wood processing industry, so we want to test as wide of a variety of tools/operations as possible.”

In a letter to Wisconsin EDUcation member instructors, Scott Nelson, president of the WCA, noted that the WDWD made the change based on feedback from wood products manufacturers in the state who opined that the skills required by the Core credential better prepared interested students to enter the workforce. “As a past architectural woodwork manufacturer, I had to agree that the Core Credential does make the student a much more employable person directly out of high school,” Nelson wrote. “Our board of directors agreed and gave the state the OK.” The bottom line, Nelson added, “(T)he WCA’s mission is to help provide a trained workforce for the secondary wood processing industry, so we want to test as wide of a variety of tools/operations as possible.”

Kettle Moraine Takes on the Core Challenge

Scott Bruening, technology/engineering teacher at Kettle Moraine High School, was one of dozens of Wisconsin high school woodworking instructors who received Nelson’s letter outlining changes to the WDWD CTE Incentive Grant program. Kettle Moraine has been a WCA EDUcation member since 2019. Over the years, the Kettle Moraine woodworking department has received tens of thousands of dollars from the WDWD for helping students earn their Sawblade Certificates.

Bruening paid close attention to how the Core Credential builds on the Sawblade Certificate to get a better handle on what changes his program would have to make to the curriculum to help students achieve their Core Credential and qualify for WDWC grants.

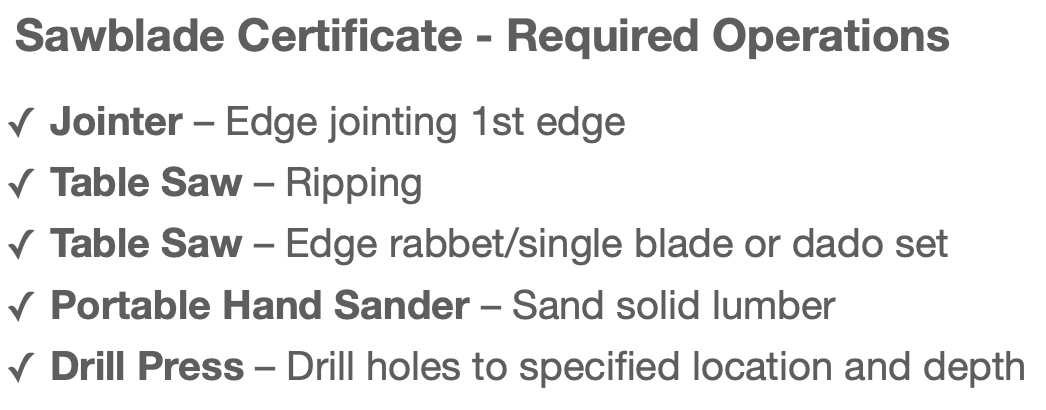

To earn a Sawblade Certificate, a student must first pass the Skill Standards Basic Measuring and layout evaluations and be successfully evaluated for the following operations each worth 2 skill points:

To earn a Sawblade Certificate, a student must first pass the Skill Standards Basic Measuring and layout evaluations and be successfully evaluated for the following operations each worth 2 skill points:

Table Saw – Ripping

Jointer – Edge Jointing First Edge

Table Saw – Edge Rabbet Single Blade or Dado Set

Random Orbital Sander – Sand Flat Pieces of Solid Lumber

Drill Press – Drill Holes to Specified Location and Depths, or Completely Through Material

The student must then pass the online Sawblade Certificate test.

In addition to meeting the Sawblade Certificate requirements, to earn a Core Credential a student must accumulate at least 120 hours experience hours and earn an additional 10 skill points by demonstrating competency in the following operations:

Planer – Planing to Thickness

Jointer – Face Jointing

Portable Power Miter Saw – Square Crosscut (90º Miter)

Router Table – Edge Shaping

Band Saw – Rough Saw Parts from a Pattern

Note: Woodworking instructors can submit a request of alternative operations to the WCA for approval if their program does not have one or more of the equipment listed.

“I was happy to see that we were pretty much already teaching our kids the Core Credential requirements,” Bruening says. “We really didn’t have to make any significant changes because we were hitting those certification pieces before.”

Bruening adds that the biggest impact of the Core Credential is the extra time it takes to evaluate each student on the five additional machinery operations that are required. Fortunately, because Kettle Moraine’s block schedule provides woodworking students 85 minutes of class time every day of the week, Bruening, a WCA accredited skill evaluator, is able to accommodate the additional Core evaluations.

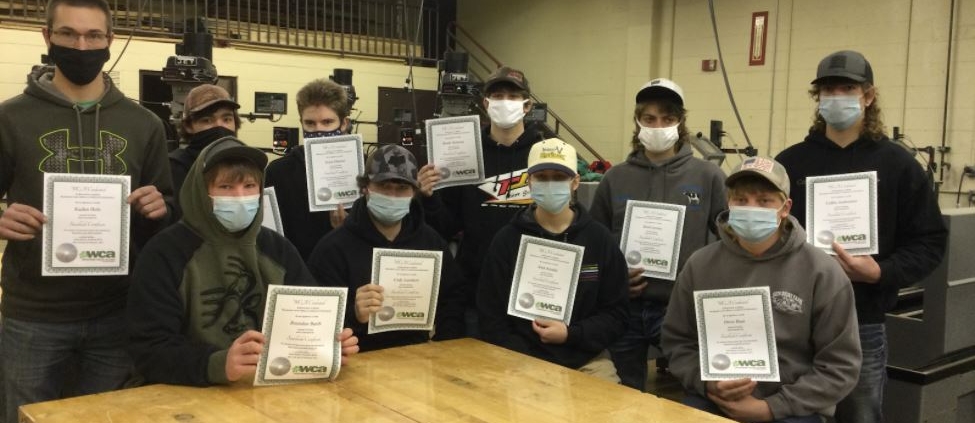

“We’ve already completed the student evaluations for both the Sawblade and Core requirements,” Bruening says. “Now all they have to do is complete their online tests which will happen soon. They will basically get their Sawblade Certificate and Core Credential simultaneously.”

Woodworking Program on the Growth Track

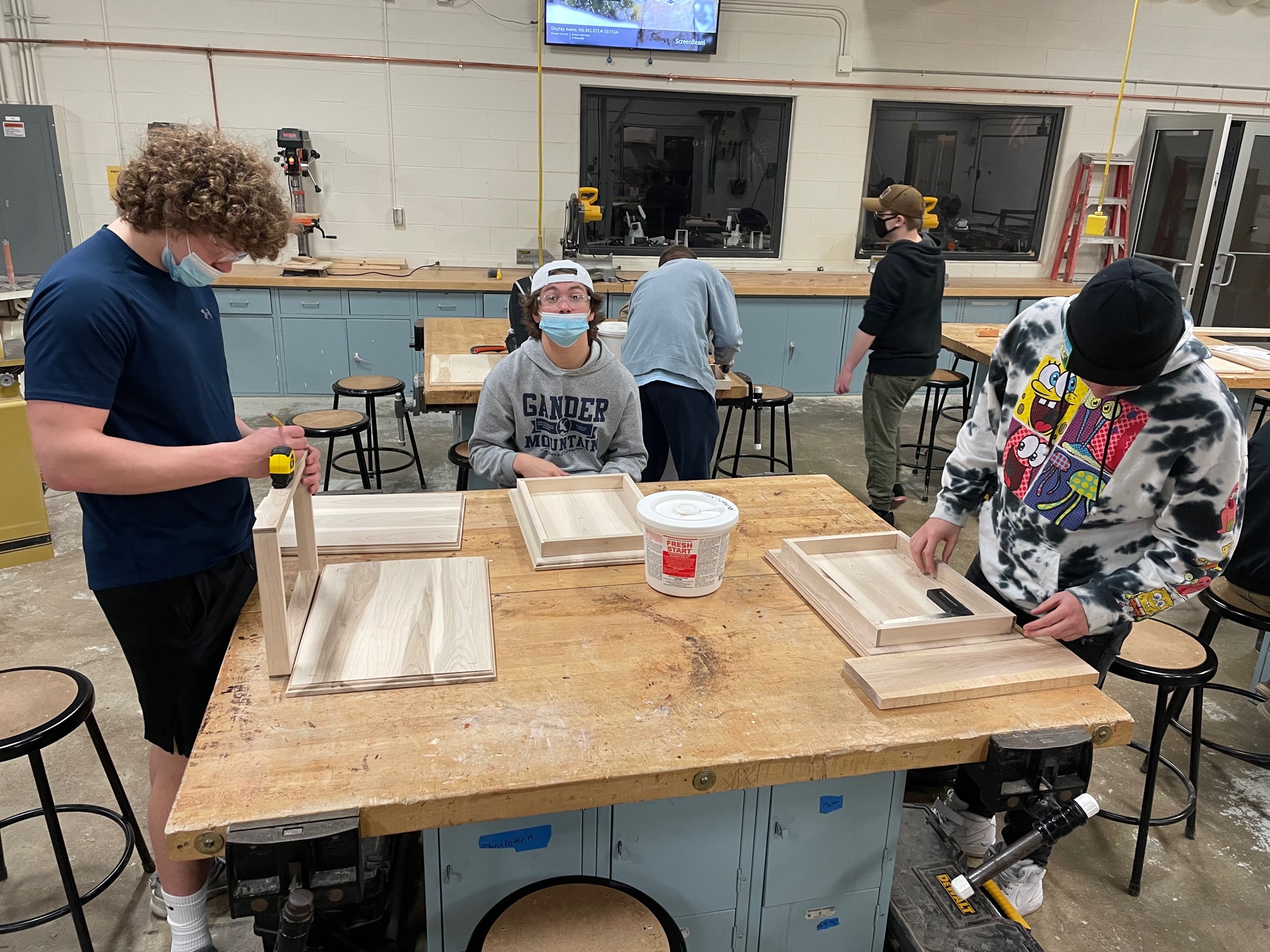

Kettle Moraine has approximately 200 students enrolled in woodworking classes this academic year. That represents about one-fifth of the high school’s student body. The staunch popularity of woodworking has been boosted by a significant increase in female participation this year. Girls now occupy about 20 percent of the nearly “sold-out” classes, Bruening says.

“I think we’re seeing more females take woodworking classes is that they have confidence they can do it and they are signing up with friends to take woodshop together,” Bruening says. “Nobody wants to be a solo rider so if they can take it together with friends it makes them more comfortable that they are not going to be the only girl in the class.”

In addition to record numbers of female participation, Kettle Moraine has expanded its woodworking program to include a Construction Cabinetmaking course. The new program is only open to students who complete Woods 1 and Woods 2.

“We have a really well-equipped woodshop,” Bruening says. “In our Woods 1 class, in addition to learning how to operate the equipment required for the Sawblade Certificate and Core Credential, students learn things like basic layout, project planning, board foot calculations and costing. In Woods 2, they tackle more complex projects like building Shaker tables with drawers and tapered legs. They learn to do face glues up because we only purchase 4/4 stock. There is more emphasis on finishing the job to a higher quality standard. It’s also an opportunity for students to work toward their WCA Green Credential.”

“In our Construction Cabinetmaking course, we introduce students to CNC-based projects using Mozaik software and a CNC Factory Viper nesting router. This allows us to teach more industry-level skills to the kids,” Bruening says. “Now we are getting more in-depth by allowing our cabinetry program to dovetail with construction. In addition to doing rough framing, the students are designing cabinets, nesting parts, assembling and finishing them. Bruening notes that the CNC router caught his eye at the 2021 AWFS Fair which he attended with the grateful financial assistance of a Greg Heuer Education Scholarship from the WCA.

Solid Community Support

Solid Community Support

Bruening says he is hopeful that the woodworking shop will be expanded to accommodate more equipment and students.

“Because we our pretty much maxed out on capacity, we really can’t do the construction program the way we would like to do it because we are absolutely land locked in terms of space and the number of hours in a day,” Bruening says. He further notes that the school’s 10,000-square-foot shop and classroom “has a class in it every hour of every day all year long.”

A recent community survey showed that residents of Kettle Moraine’s school district rank Career Technical Education right near the top of academic programs that they would like to see improve and grow. “I was hard pressed to find a parent at our last open house who was not impressed with what we are doing in our program. It’s encouraging to know that the community, including those without kids at our school, support the skilled trades.”

“I think being a WCA EDUcation member helps validate our program,” Bruening says. “The skills that the kids use to earn their Core Credentials are directly tied to the projects they create, many of which they have pride taking home to mom and dad.”