Zooming in on the Virtual 2021 SkillsUSA Cabinetmaking Championships

The technical chair of the AWI SkillsUSA Committee discusses the challenges and ultimate satisfaction of pulling off this year’s national competition remotely.

The annual SkillsUSA National Leadership and Skills Conference is the most anticipated event for students of high school and postsecondary career and technical education programs across the nation. Loaded with pageantry and energy, the nearly week-long event is often likened to the Olympics of CTE, with Gold, Silver, and Bronze medals being awarded to the top finishers.

In normal times, SkillsUSA occupies a space equivalent to 31 football fields. In 2019, the national championships fielded more than 6,500 contestants in 106 separate events, including one devoted to cabinetmaking.

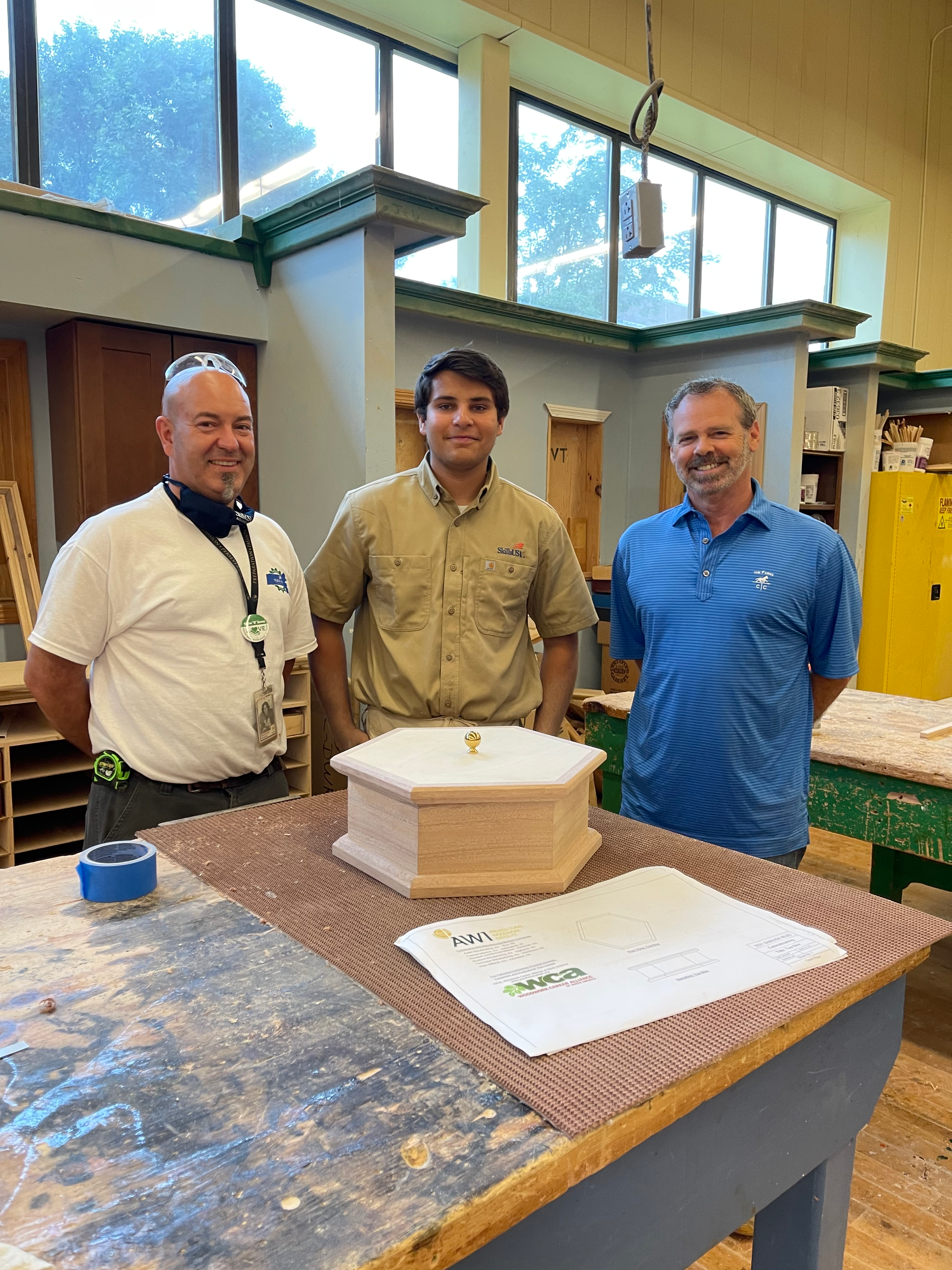

Max Soares, the winner of the 2021 SkillsUSA Cabinetmaking competition, is flanked by his high school advisor Joseph Arruda, left, and Mike McNulty, 2019 AWI president, who served as his proctor.

But these are not normal times. Even though the coronavirus pandemic is now largely on the wane in the United States, a decision was made many months before to hold this year’s competition as a virtual event rather than at the Georgia World Congress Center in Atlanta as had been planned during the week of June 14.

As disappointing as that decision might seem, it’s not nearly as bad as the one that had to be made last year when the fast-spreading virus caused SkillsUSA to be canceled altogether.

Cheers to the Winners

Six students, three each in the separate high school and college competitions were honored in this year’s SkillsUSA Cabinetmaking Championships.\

High school student winners included:

- Gold: Max Soares, Greater New Bedford RVTHS, New Bedford, MA

- Silver: Hayden Clarke, College Station High School, College Station, TX

- Bronze: Cole Murray, Green River High School, Green River, WY

College student winners included:

- Gold: Christopher Midgley, Indian Capital Technology Center-Sallisaw, Sallisaw, OK

- Silver: Chris Todd, Wayne State College, Wayne, NE

- Bronze: Ryan Faust, Saint Paul College, Saint Paul, MN

AWI Takes the Lead on Cabinetmaking Championships

The cabinetmaking competition was organized by the Architectural Woodwork Institute’s SkillsUSA Committee, chaired by Kristine Cox of Rowland Woodworking. Kent Gilchrist, treasurer of the Woodwork Career Alliance and chair of the AWI Education Foundation, serves as SkillsUSA cabinetmaking technical chair.

Gilchrist carved out some time to answer questions about this year’s most unique SkillsUSA Cabinetmaking Championships.

Rich Christianson: I assume staging this year’s SkillsUSA Cabinetmaking competition virtually wasn’t easy. What were some of the key challenges you had to overcome?

Kent Gilchrist: This was a lot more work. We’ve spent years perfecting our live competition and we had to do this one from scratch.

The first challenge was crowning the individual state champions to compete in the national competition. Most states ran virtual competitions, but some actually met in person because they didn’t have restrictions. Then there were other states that did not allow any equipment to be used. For example, in North Carolina, they could have a competition but they couldn’t use any equipment.

Christianson: Did the patchwork quilt of state rules negatively impact the number of students who competed in nationals?

Gilchrist: Yes, unfortunately, they did. Typically, we have 65 to 70 competitors. This year we only had 26 competitors. This includes five who registered from postsecondary and 21 from secondary schools. I believe we had one scratch at each level.

Christianson: So, even with far less than half the qualifying competitors, as usual, you pushed forward. What were the basic mechanics of conducting the high school and college cabinetmaking championships virtually?

Gilchrist: Each of the students completed a technical assessment, which we borrowed from the WCA. We used the WCA’s Green credential assessment consisting of 40 multiple choice questions to test their woodworking knowledge. We also had them create a cut list from a past SkillsUSA national cabinetmaking competition project. This is something they would normally do at an in-person competition.

In addition to these two components, they had to take a professional development test which is mandatory by SkillsUSA and they had to turn in a resume. Finally. we had what we called the “build project.” On their specified build day, they competed from their own classroom in front of a stationary camera. Each of the student competitors was joined by their advisor, usually their woodworking instructor, and a proctor.

This wooden tea box, the build project for the 2021 SkillsUSA cabinetmaking competition, proved more challenging than expected for many of the contestants.

Christianson: I get the advisors being present. What more can you tell me about the proctors? What was their job?

Gilchrist: One of the jobs of the proctors was to use a roving camera to take different angles of the student working on his or her project as requested by the judges.

Here’s the fun part. The first challenge we had was finding proctors. We went through our AWI network and industry connections. We reached out to as many people as we could in a short period of time because we didn’t know who the competitors were until three to four weeks before the national competition. Once we figured out who each competitor was and where they were located, we tried to establish where we could get a proctor in that location.

Our goal was to have industry-related proctors at each of our sites. But we probably ended up being able to pull only about 60 percent from the industry. They were a mix of supplier members, AWI members, and wood products manufacturing members. Some were retired members of AWI who stepped up to help.

Christianson: If the main job of the proctor was to operate the roving camera, why was it desirable to find people with industry experience?

Gilchrist: A couple of reasons. One, the proctor was someone who was also kind of keeping tabs on the honesty level of what was going on there. We needed to find someone to observe the student working who was not biased in any way. The other reason that we wanted to have proctors there from industry was so that we could introduce the industry to the schools. When SkillsUSA first announced they wanted to do this virtually, we saw it as an opportunity to build relationships between industry and education. It actually worked out well. We had some proctors who had an epiphany that we actually have schools with high-quality woodworking programs that are well-equipped.

In cases where we could not find a proctor, the school’s advisor found a trustworthy assistant to serve as a proctor.

Christianson: Which online platform was used for the competition? How did it work out?

Gilchrist: This was all done by Zoom and it overall worked out great.

On the Monday of the competition week, we held a two-hour-long orientation. We gave the competitors the scope of the contest and briefly showed them the project plans of the tea box that they were going to build. We also discussed the different aspects of the competition.

We broke the project build days into three groups, Eastern time zone, Central time zone, and Mountain and Pacific time zones. Each day we sent out a specific link to the schools that were competing that day. We probably had 30 hours of Zoom calls over four days, including the orientation and the three competition days. The competitors had six hours to build their project.

During the competition, we would communicate either through voice or through chat with the students, proctors, and advisors. For example, we would instruct them to adjust their camera or to zoom their camera in on the project or task. We could also signal the competitor to ask a question and they could ask us a question as well.

I think using Zoom for the competition turned out better than we had expected. It had its challenges, but I think the schools were used to the formats having used them. They had already been doing this for a year for remote learning during the pandemic so to have another event run through Zoom was not really that much of a transition for them.

Christianson: In normal times, when the national competition is held live in a host city like Louisville in 2019, each of the contestants uses the same equipment and materials. Obviously, that was not the case this year. I guess the upside is that students ran equipment they were used to working with but on the other hand some of them might have had newer or better equipment. Did this put some of the competitors at a disadvantage?

Gilchrist: That and the six-hour time limit were important factors that we considered when we developed the plans for this year’s build project. We knew the project had to be fairly simple, at least as far as the tools they were going to use because we did not know what kind of equipment each contestant had in their classroom. Their primary equipment included a table saw, a miter saw, and a few little hand tools, such as a block plane, a sanding block, and then either a pin nailer or some finished nails. We kept the project simple because we did not know what kind of equipment each contestant had in their classroom.

Interestingly, when we previewed the project during the orientation Zoom call, I could see this look of surprise on many of the competitors and their advisors. I believe they thought this was a very simple project. Many were probably thinking, “Wow, that’s all that there is? We’re just going to build a box.”

Much to their surprise, the project offered some interesting challenges they may not have considered. The box was a hexagon and if they cut the top or bottom wrong, the project was wrong. If they didn’t get their miters just right, then it was absolutely wrong. We gave them the dimensions and told them the parts were 30-degree angles. But we didn’t tell them they had to bisect the angles. There were some mistakes with either a wrong size part or angles cut on the wrong side of the line. There were some under-sized boxes, which is typical. Mistakes happen when a contestant is nervous during a competition. We see that at nationals all of the time.

Ryan Faust, a student at St. Paul College, won the bronze medal in the post-secondary SkillsUSA Cabinetmaking Championship.

Christianson: How were the judges able to accurately gauge if a part’s tolerance was off by just a fraction of an inch?

Gilchrist: That was another role of the proctor. At the end of the competition, the proctor’s job was to give us six photographs of different views based on guidelines and sample pictures we gave them. They would just match those pictures and give us the same image with the student’s project.

Christianson: It’s a bummer that the students didn’t get the normal SkillsUSA national championships experience. They didn’t have the opportunity to travel and represent their state or to meet their fellow competitors. Yet, considering the competition was entirely canceled last year, how do you feel about what was accomplished this year?

Gilchrist: I think it was the right choice to do it virtually and I think the students who competed were satisfied with what they were able to do. Even though it wasn’t in-person, the students were still able to take a lot away from it.

It was interesting watching the awards ceremony on Zoom. All of the medalists were encouraged to have watch parties with their families and friends. It was great to hear people cheer when each of their names was called. That was exciting. I knew all of that work was worthwhile.