Teacher’s Chime in on Teaching Woodworking during a Pandemic

A student of Tremper High School, Kenosha, WI, measures a board. The woodworking class is using WCA measurement training materials and quizzes.

Survey sheds light on how WCA EDUcation instructors are adjusting to their roles.

How are high school woodworking instructors coping with the unprecedented challenges of teaching their students during the COVID-19 crisis? How many are teaching courses in the classroom this fall versus remote? And depending on whether they are able to conduct classes face-to-face or online, what is the focus of their lesson plans?

These are some of the questions that the Woodwork Career Alliance of North America sought to answer in a recent survey of EDUcation member instructors. The study represented a follow up to a survey the WCA conducted in the spring shortly after the vast majority of the high schools abruptly shut down and pivoted to online learning due to the novel coronavirus pandemic.

The number of valid responses generated by the survey – 24 out of a possible 135 – is insufficient to draw any solid statistical conclusions. But the anecdotal responses speak volumes about the kinds of issues high school woodworking instructors are faced with and some of the things they are doing to best play the cards that they’ve been dealt.

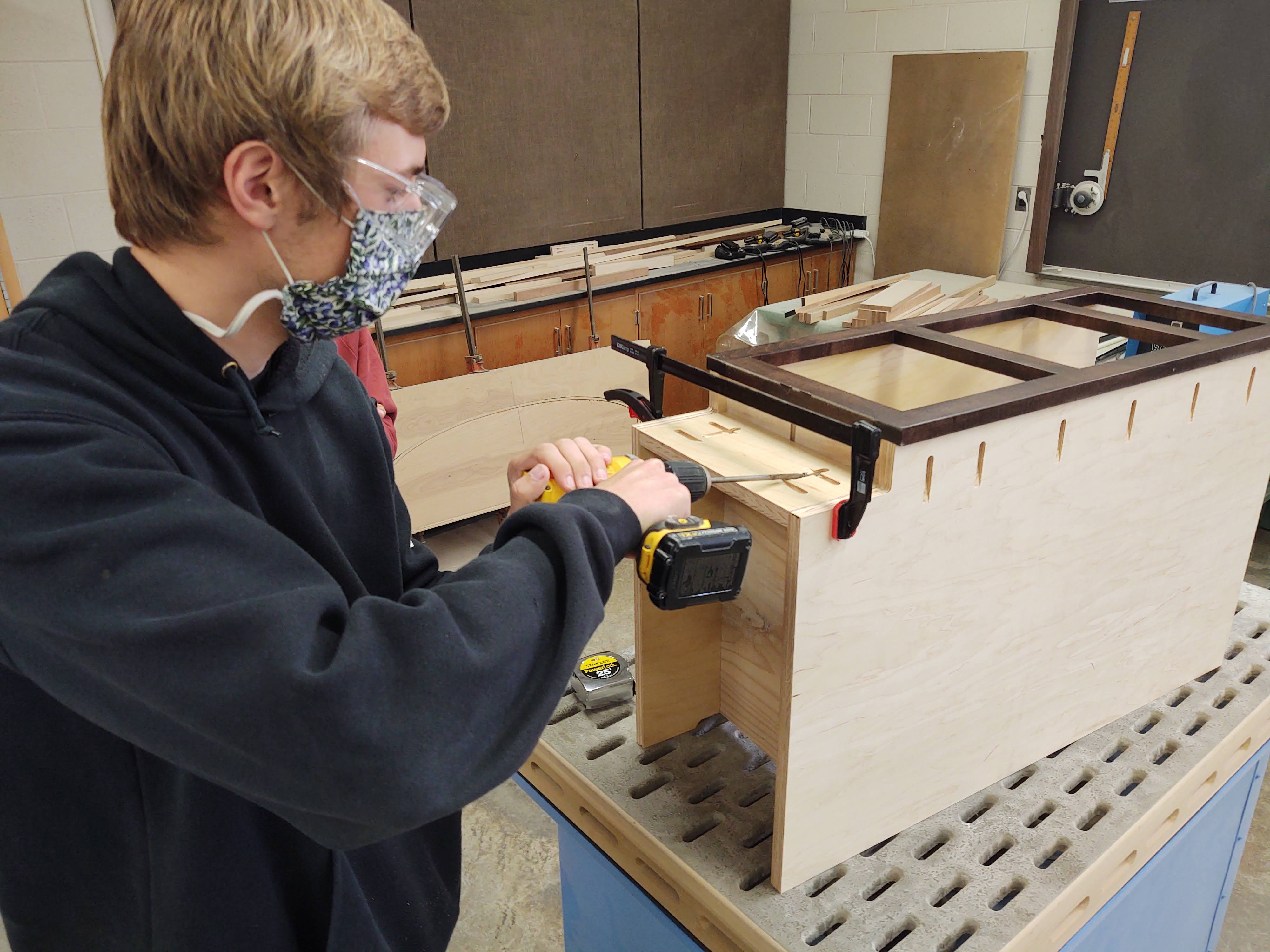

A handful of the instructors were willing to be quoted by name and a few of them were gracious enough to send photos illustrating some of their students’ woodworking assignments. At the conclusion of this article are some of the longer responses garnered by follow-up questions to some of the instructors who went on the record.

Following are some of the Fall survey’s findings, including related comments.

Classroom vs. Online Instruction

Fifty percent of the high schools were fully open, though some had adopted A/B day scheduling to limit access to their woodshops to half of the enrolled students at a time. Additionally, 32% of the schools had adopted a hybrid model with some in-person and some online learning. Eighteen percent of respondents said their schools were closed with half saying they were teaching exclusively online and half saying they were not teaching woodworking this fall.

“Even though we are fully open, some students have chosen to do the same class virtually. I’m struggling with how to do the hands-on woodworking virtually.”

“I have students in class and online simultaneously,”

Woodworking Course Enrollments

Forty-six percent of the instructors said they have 41 or more students in their courses this fall. Another 46% said they have 11 to 30 students while the remainder are not teaching woodshop this semester.

In comparison, half said their current enrollment is about the same as Fall 2019. Thirty-six percent said they have fewer woodworking students and 14% said they have more students this fall than last.

Online Collaboration Platforms

Google Meet/Hangouts is being used by 59% of the respondents for online instruction. Zoom with 32% is the second most popular collaboration platform.

Use of WCA Online Training Resources

The WCA maintains a library of videos and other training materials for the exclusive use of EDUcation and MANufacturing members.

Fifty-five percent of the woodworking instructors said they are integrating WCA resources into their fall 2020 curricula.

Woodworking machinery demonstration videos created by Patrick Molzahn, director of cabinetmaking and millwork at Madison College, are the most often cited resource that are being accessed.

“The online evaluator training is helpful, as our Patrick Molzahn’s videos and WCA instructor files.”

“I’ve had students read some of the articles in Fine Woodworking.”

“I have downloaded various docs and assignments to help guide (my students) through the second semester.”

The survey also asked woodworking instructors to recommend the types of instructional materials they would like the WCA to add to its library. Topping the list of asks were videos related to machinery, power tool and general shop safety.

Other requested educational materials include:

“More combination-type projects that involve using several different tools for teaching students how to use.”

“Demonstration videos geared toward showing students various types of joinery – mortise and tenon, dovetail, rabbets, etc.”

“We need some type of online virtual machine training,” suggested one respondent. “Just like a video game except for woodworking machinery. Log in and operate a piece of machinery like you do on a video game using a weapon or door to navigate a landscape.”

Teaching Woodworking Online

It goes without saying that it’s hard to teach high school students woodworking when they can’t get the hands-on experience in the school’s woodshop. So, what are teachers doing with their online instruction? A few examples:

“We are working on a video platform where we record lessons that I do in the shop.”

“We have access to the woodshop at this time but if we lose access I will be using more of Patrick Molzahn’s checklists and videos.”

“Pretty much everything is online. We are able for several students at a time to meet face-to-face and get some shop experience.”

“Students online will be meeting knowledge standards through creative assignments such as creating videos and blogs.”

“We are working in the shop, but woodworking videos are assigned.”

“While virtual is not an ideal form of teaching a ‘craft’ that is so experiential, there is still a passion that can be felt while watching someone who is immersed in doing what they love. That will be my aim in teaching this semester.

Parting Words

“It’s very tough and the shop experience is not there for the majority of my students.

“I can’t wait for my classes to meet in person again.”

Five Longer Takes on Teaching

Woodworking These Days

“I have 24 students in the shop this semester compared to 42 last semester. Students had a choice between meeting face to face or virtually for academic classes but not for my woodworking classes. My two level 1 classes are just learning tool use and safety. They have made some succulent planter boxes, a wall plaque and just completed a kitchen shelf. Our next project will be a spice rack. My level 2 class just completed a dog kennel for a local K-9 officer and are now working on adirondack chairs and corn hole boards which we sell as a fundraiser.” – Nick Daniels, skilled trades instructor and SkillsUSA advisor, Avery County High School, Newland, NC

“About half of our students chose to be total remote learners. The rest of the students were split into 2 groups A & B. That leaves me on average about 5 or 6 students per class face-to-face. I have to put everything online for my total remote students who follow what we are doing face-to-face. The only difference is that my face-to-face students get access to the shop for only 70 minutes at a time, twice a week. My level 1 students are building a small, milking stool that allows the students access to the table saw, radial arm saw, planer, jointer and scroll saw. Also, the students get to assemble this stool with glue and our pneumatic tools. My level 2 students are working on their OSHA certification now.” – Doug Talbert, woodworking instructor, Albemarle High School, Albemarle, NC

“We are currently face-to-face but and our students are adapting well to protocols for cleaning and mask wearing. But we are beginning to see schools in neighboring counties closing due to COVID-19 cases. Just in case, I am moving from our furniture/cabinetry curriculum to carpentry. This will allow something ‘new and exciting’ that we don’t typically do to have some hands-on projects at home. We have had donations from a construction company directed to online curriculum and modeling supplies to build models. I will also be offering the opportunity to self-motivated kids to build scale model furniture if they so choose, which will require them to get an approved learning plan with me. We also just received a grant for a maple syrup program I’ve been working on that has allotted $7,500 to build a sap shack. WCA standards will still be applied. Wisconsin has a Construction Career Pathway that recognizes WCA certification so I will still reinforce any WCA content I am able to. Here is where the virtual situation may benefit us in regard to WCA, I tend to lean so hard on hands on and getting the kids in the shop that I often lack in the “book work” end of the requirements I need to successfully get kids certified. I’m hoping that this allows me to do a better job at getting kids their WCA Sawblade certification.” – Roger Peterson, woodworking instructor, Hurley High School, Hurley, WI

“I have some students in person and some who opted for at-home schooling who are learning the same thing. The “knowledge content” required is identical but how it is demonstrated will be different. For example, in class they will build a birdhouse and demonstrate the ability to build. Online they will be given documentation and watch the house being built and then be required to explain how to build. The online project essentially becomes a how-to video, blog, etc. A test will cover the content of each unit will be done by both groups. I downloaded the WCA’s docs and assignments for teaching measuring for my second semester students to get the PMI measuring certification. In class, students just finished safety lessons are will build Little Free Libraries that a local non-profit called Garden of Eatin’ requested we build for them.” – AJ Mueller, technology educator instructor, Tremper High School, Kenosha, WI

“I currently have six classes each with about 15 students per week and we have full-time access to the shop. Among our projects, we’re making long boards, acoustic guitars and kitchen cabinets. I’m using Patrick Molzahn’s videos and online checklists and I’ll be using them even more if we lose use of the shop. I have created Google Forms to pre-test students on all of the machines and information necessary so that students can then take the written online exam to earn their WCA Sawblade certificates.” – Mark Smith, industrial technology teacher, Reed-Custer High School, Braidwood, IL

The pandemic has forced me to update my program in ways I always new I needed too. I am using many of the videos supplied by the Woodwork Career Alliance to automate my program. Students go online now to become familiar with machine safety and operation and test online using Google forms. Now, greater focus can be placed on the hands-on part of my curriculum during the face to face time with the students. I am taking my lead from Patrick Molzahn of Madison College who has been doing this for years,

Mark Smith

Reed-Custer High School